IMPORTANT NOTE:

THE PURPOSE OF THIS INSTRUCTION MANUAL IS TO ASSIST YOU IN THE PROPER AND SAFE ASSEMBLY, OPERATION, SERVICING AND STORAGE OF YOUR ULTRA-HIGH PRECISION SPRAYER ARA™.

PLEASE READ THROUGH THIS INSTRUCTION MANUAL COMPLETELY FOR A FULL UNDERSTANDING OF HOW TO OPERATE AND MAINTAIN YOUR EQUIPMENT.

KEEP THIS MANUAL IN A SAFE, CONVENIENT PLACE FOR FUTURE REFERENCE.

WARNINGS

DO NOT TAMPER WITH, DISASSEMBLE, OR OPEN any of the parts or components of the Ultra-High Precision Sprayer ARA™ unless specified in this Instruction Manual as this can cause serious injury and will void the product warranty.

DO NOT ALTER, MODIFY, OVERRIDE, or DEFEAT the software or hardware components. Any unauthorized modification could impair the function and/or safety of this product and result in serious injury and will void the product warranty. Use of accessories not approved or recommended by the manufacturer can potentially cause injuries.

READ and UNDERSTAND this INSTRUCTION MANUAL completely before using this machine. Assemble, test, and use the Ultra-High Precision Sprayer ARA™ only in accordance with these instructions.

READ and FOLLOW all CHEMICAL LABEL instructions for chemicals that are used with this Ultra-High Precision Sprayer ARA™. Herbicides, fungicides, pesticides and insecticides are hazardous chemicals. Improper handling of chemicals can result in serious injury or illness, or cause damage to humans, animals, or the general environment.

KNOW EMERGENCY and FIRST AID procedures BEFORE handling chemicals. Sprayer leaks, bodily chemical contact, poisoning, and spills require immediate response.

AVOID inhaling, ingesting, or coming into direct contact with any chemicals.

WEAR personal protective gear when filling, using, cleaning, and servicing the machine.

KEEP children and pets away from the machine.

EXERCISE CAUTION in vehicle handling to avoid loss of control or risk of tank or sprayer overturning.

ALWAYS keep a fire extinguisher rated “ABC” nearby.

Improper use of the sprayer or handling of chemicals could result in serious injury or illness to the operator or nearby people or animals or could cause damage to the environment.

WARNING

Emergency Spraying Stop

ARA™ is equipped with a spraying stop control device at the driver’s position, in compliance with ANSI/ASABE AD4254-6:2020.

-

To immediately stop spraying, press the “Spraying” button.

-

To end the current mission, then select “End Mission”.

This procedure safely stops the flow and minimizes dripping from each nozzle.

Persons using, maintaining, or repairing the machine are obliged to observe the following rules:

-

Be trained in the handling of herbicides, fungicides, insecticides, or fertilizers and their dangers.

-

Have been trained by a manufacturer-approved trainer in aspects concerning:

-

Safety

-

Accident prevention

-

The use of the machine

-

Maintenance of the machine

-

-

Have read and understood the meaning of all safety signs on the machine.

-

Be familiar with the characteristics of the machine and its use.

-

Strictly observe the information in this manual, especially the points concerning safety.

-

To scrupulously respect the rules of occupational medicine and road legislation.

-

Use the machine only for its intended purpose.

-

Do not modify the machine or use spare parts from suppliers not explicitly approved by the manufacturer.

-

Never entrust the machine to anyone who does not meet the criteria listed here.

-

Comply with the regulations in force concerning mandatory periodic inspections.

-

Contact your Ecorobotix dealer if any part of this manual is not completely understood.

INFORMATION

Failure to comply with these rules may result in revocation of the warranty and release the manufacturer from liability.

Periodic inspections

Comply with current regulations regarding mandatory periodic inspections of pesticide application equipment.

Prior to first use

-

Purge spray systems if they contain antifreeze. The antifreeze solution should never be sprayed or applied to the environment. Use an appropriate liquid recovery facility for this operation. Wear gloves to avoid direct contact with the antifreeze.

-

In all cases, flush spray lines with water.

-

Grease the transmission.

General chemical safety

DANGER

CHEMICAL SPILLS, SPRAYER LEAKS, PERSONAL CONTAMINATION, AND POISONING ARE ACCIDENT SITUATIONS THAT REQUIRE AN IMMEDIATE RESPONSE.

IN THE EVENT OF A CHEMICAL ACCIDENT INVOLVING CONTAMINATION OR POISONING, FOLLOW FIRST AID INSTRUCTIONS ON THE CHEMICAL LABEL AND IMMEDIATELY CONTACT POISON CONTROL FOR FURTHER ADVICE 1.800.222.1222. IF VICTIM COLLAPSES OR IS NOT BREATHING CALL 911.

READ and FOLLOW all CHEMICAL LABEL instructions for chemicals that are used with this ARA™ machine. Herbicides, fungicides, pesticides and insecticides are hazardous chemicals. Improper handling of chemicals can result in serious injury or illness, or cause damage to humans, animals, or the general environment.

KNOW EMERGENCY and FIRST AID procedures BEFORE handling chemicals. Sprayer leaks, bodily chemical contact, poisoning, and spills require immediate response.

AVOID inhaling, ingesting, or coming into direct contact with any chemicals.

WEAR personal protective gear when filling, using, cleaning, and servicing the sprayer.

Before spraying

-

Sprayer Prep: ALWAYS inspect and prepare the sprayer before use according to the directions provided in this manual.

-

Wind Speed: NEVER spray when wind exceeds 4 MPH in order to minimize spray drift.

-

Clear Area: ALWAYS keep work area clear of people and pets.

-

PROTECTIVE EQUIPMENT: ALWAYS WEAR protective equipment as directed on the chemical label or in this manual.

-

Operator Age: To operate this sprayer, you must be 18 years of age or older. Pesticides are extremely toxic to children.

-

Chemical Label: ALWAYS READ and FOLLOW all chemical label instructions.

-

State & Federal Laws: ALWAYS refer to state and federal regulations with regard to the application of a particular chemical you plan to use.

-

Flammables: NEVER use any flammable chemicals

-

Corrosives: DO NOT use corrosive chemicals, such as bleach, in the sprayer. They can weaken the sprayer and its parts, resulting in leaks. Always check with chemical manufacturer for compatibility with sprayer.

-

Emergency Procedures: Before handling chemicals, carefully review the “Statement of Practical Treatment” on the chemical label.

During spraying

-

Children & Pets: ALWAYS exercise extra caution when spraying near areas accessible to children and pets.

-

Eating & Smoking: DO NOT eat, drink, smoke, rub your eyes or touch any part of your bare skin while handling chemicals and spraying.

-

Heat & Flames: DO NOT spray near open flames or sources of heat.

-

Spills: ALWAYS clean up spills immediately per instructions on the chemical label.

-

Unattended: ALWAYS turn off vehicle and set brake or block wheels.

After spraying

-

Clean Machine: Clean the machine immediately after use according to the directions provided in this manual.

-

Decontaminate: ALWAYS decontaminate yourself immediately after you are finished with spraying and handling chemicals. Wash all exposed areas of the body with soap and water. Remove and launder clothing.

-

Chemical Disposal & Storage: ALWAYS dispose or store remaining chemicals properly as recommended on the chemical label.

-

Health Monitoring: Monitor the health of operators who are frequently exposed to pesticides, as recommended by the chemical label.

Personal protective equipment (PPE)

Plant protection products PPE

When handling plant protection products, even diluted ones, it is mandatory to wear appropriate personal protective equipment (PPE):

-

Nitrile or ultranitrile gloves.

-

Neoprene gloves if ketone is present in the formulations.

-

PPE clothing (coveralls or jacket and pants) certified to EN ISO 27065:2017.

-

A long-sleeved chemical protective apron (PB category III type 3) to be worn when mixing/loading and washing the sprayer.

-

Protective glasses.

-

A breathing mask with filters.

In addition, the following points should be observed:

-

Absolutely avoid certain materials such as latex or PVC. Watertightness is not a sufficient criterion for the selection of protective equipment materials.

-

Replace PPE as soon as it shows signs of wear.

-

Store PPE in an area away from products.

-

Change the mask filter cartridges every 40 hours during periods of heavy use.

-

Replace the mask at least once a year.

-

Dust masks do not provide sufficient protection against plant protection products.

Storage of PPE

Two boxes are supplied with the machine for storing PPE:

-

One for clean PPE.

-

One for used PPE.

Other PPE

Some jobs may require the wearing of PPE adapted to their nature. The following list indicates the most common PPE but is not exhaustive. Ensure that all PPE required by safety standards is available and functional.

-

Ear protection.

-

Protective glasses (medical glasses are not enough).

-

Safety shoes.

-

Protective gloves.

-

Helmet

-

Etc.

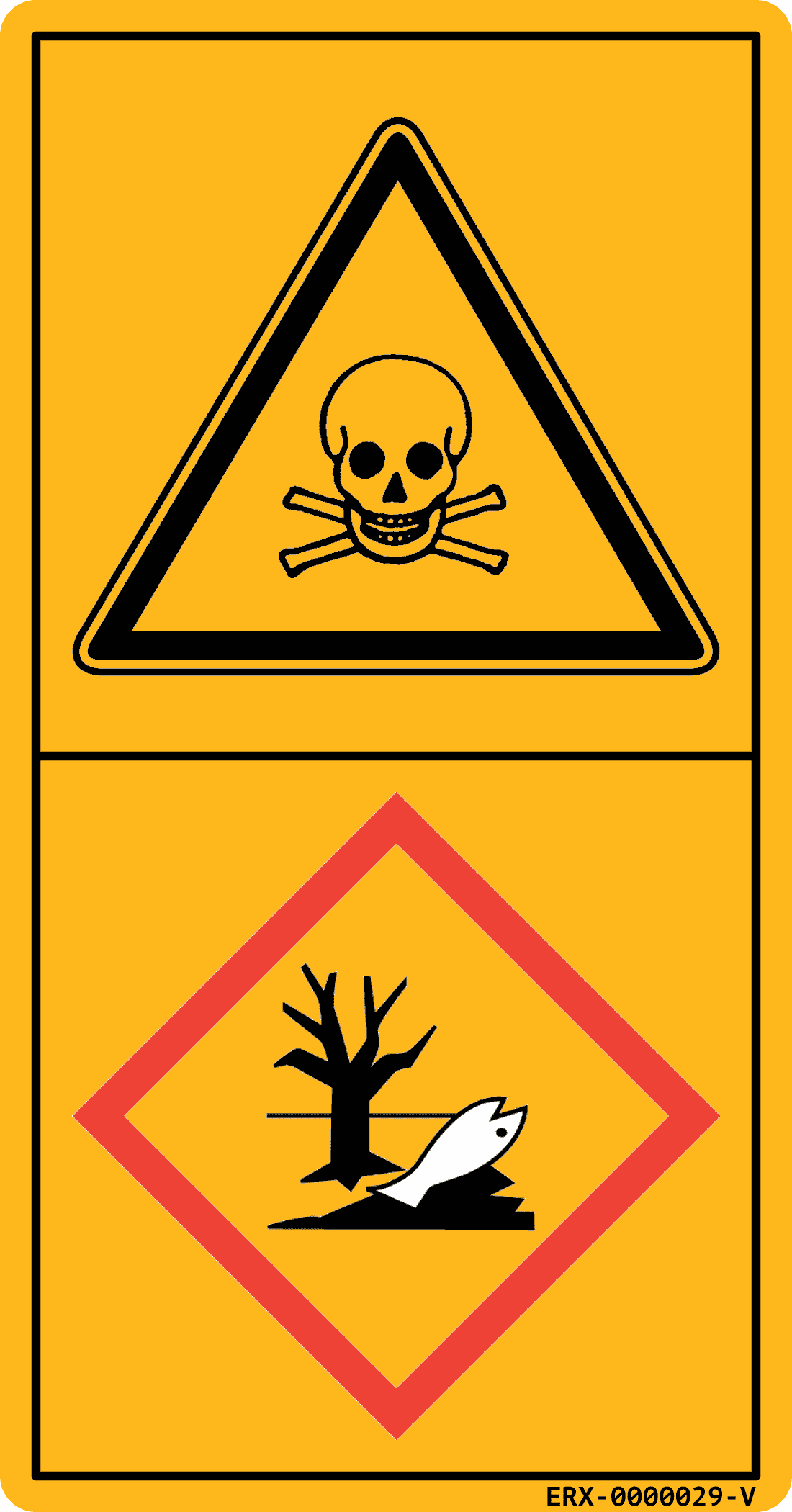

Toxic products

-

Before working with toxic materials, make sure a complete first aid kit is available.

-

Most of the liquid products necessary for the proper use of the machine can present important health risks. Products such as fuels, oils, solvents, antifreeze, and cleaning products should not meet the skin, eyes, and mouth.

-

In case of incident, consult a doctor.

-

Strictly follow the instructions on the safety labels on the containers of toxic products.

-

Ask the suppliers of the products used about:

-

The effects of these products on humans and the environment.

-

Appropriate storage conditions.

-

Appropriate conditions of use

-

Precautions to be taken for product disposal.

-

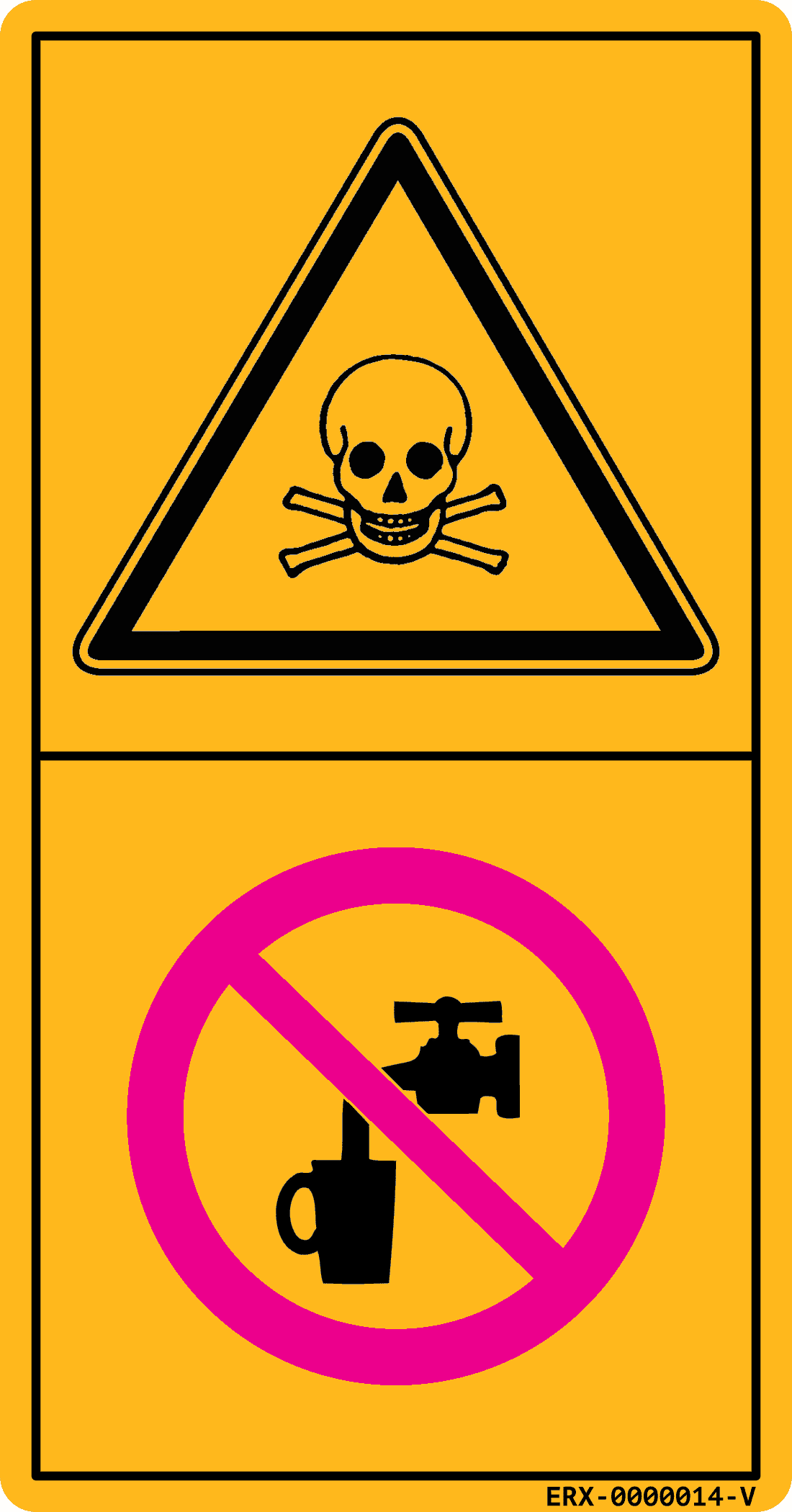

Phytosanitary products

In the presence of herbicides, fungicides, insecticides, or fertilizers, the following precautions must be scrupulously respected:

-

Keep untrained people away, especially children.

-

Do not eat, drink, smoke or vape.

-

Make sure that the various controls of the machine, or any parts that can be handled with bare hands, are clean and free of splashes of plant protection products.

-

Never clean inlets, nozzles, hoses, or other small parts by blowing with your mouth.

-

Do not fill the tanks with a dip hose.

-

Never connect directly to a water supply system for the preparation of treatments.

-

Do not pump water from natural environments to preserve the environment.

-

Ensure that all liquids are recovered and recycled in accordance with applicable standards and regulations.

-

Take the necessary measures to avoid tank overflows and product spills outside the environment to be treated.

-

Read and follow the instructions and directions for use of the products.

-

Remember that these products are particularly harmful to wildlife and insects, especially pollinating insects.

-

Follow the rules published in the instructions for use, in the safety sheets and in the advice documents.

-

Store herbicides, fungicides, insecticides, or fertilizers in a place with a watertight floor allowing the recovery of product leaks.

-

If the storage area for plant protection products is of the “fixed” type, it must be sufficiently ventilated, with a door fitted with a lock and inaccessible to children and unauthorized persons.

-

If the storage area for plant protection products is of the “mobile” type, the remaining packages, whether partially or totally empty, must be kept out of reach of children.

-

Ensure that the products and their packaging cannot fall, break or be accidentally spilled during transport or work.

-

Rinse the crop protection product containers and add the rinse dilution to the spray tank before spraying.

-

Pierce the packaging after rinsing to prevent reuse.

-

Spray at a minimum distance from the edges of ditches and waterways, in accordance with current legislation.

-

Dilute the products so that their concentration is divided by at least a factor of 100. To do this, perform 4 rinses or one continuous rinse with clean water.

-

Drain circuits and tank bottoms on the treated crop or on an authorized crop while avoiding runoff.

-

Drain away from streams, ponds, wells, water catchments and residential areas.

INFORMATION

In any case, comply with the legislation in force.

Guidelines for water protection

Filling and washing the sprayer

-

Fill only on a sealed area connected to an active slurry tank or treatment system.

-

Under no circumstances shall this space be connected to the sewage or wastewater pipes.

-

For clean filling, use a non-return valve or a filling arm for mains water.

-

If necessary, use foam suppressants.

-

Monitor the filling.

-

Avoid leftover spray mixture by using the spray mixture calculator supplied with the machine and a water meter for filling.

-

Rinse preparation tools and empty containers 3 times. Empty the rinse water into the spray tank.

-

Carry out the first filling of the booms on the washing place.

In the field

-

Never treat roads, paths, and drains, not even to prime the sprayer booms.

-

Flush the main tank and the sprayer circuit 4 times or continuously on the plot.

-

Dilute and distribute any remaining spray mixture on the plot.

After spraying

-

Wash the entire sprayer.

-

Dispose of leftover mixture or wash water in a slurry pit or a plant protection effluent treatment system.

-

Never dispose of the residues in the clear water or waste water system, because even after rinsing, the sprayers contain residues of active substances.

INFORMATION

1 g of phytosanitary product pollutes 10 km of brooks! Every gram counts!

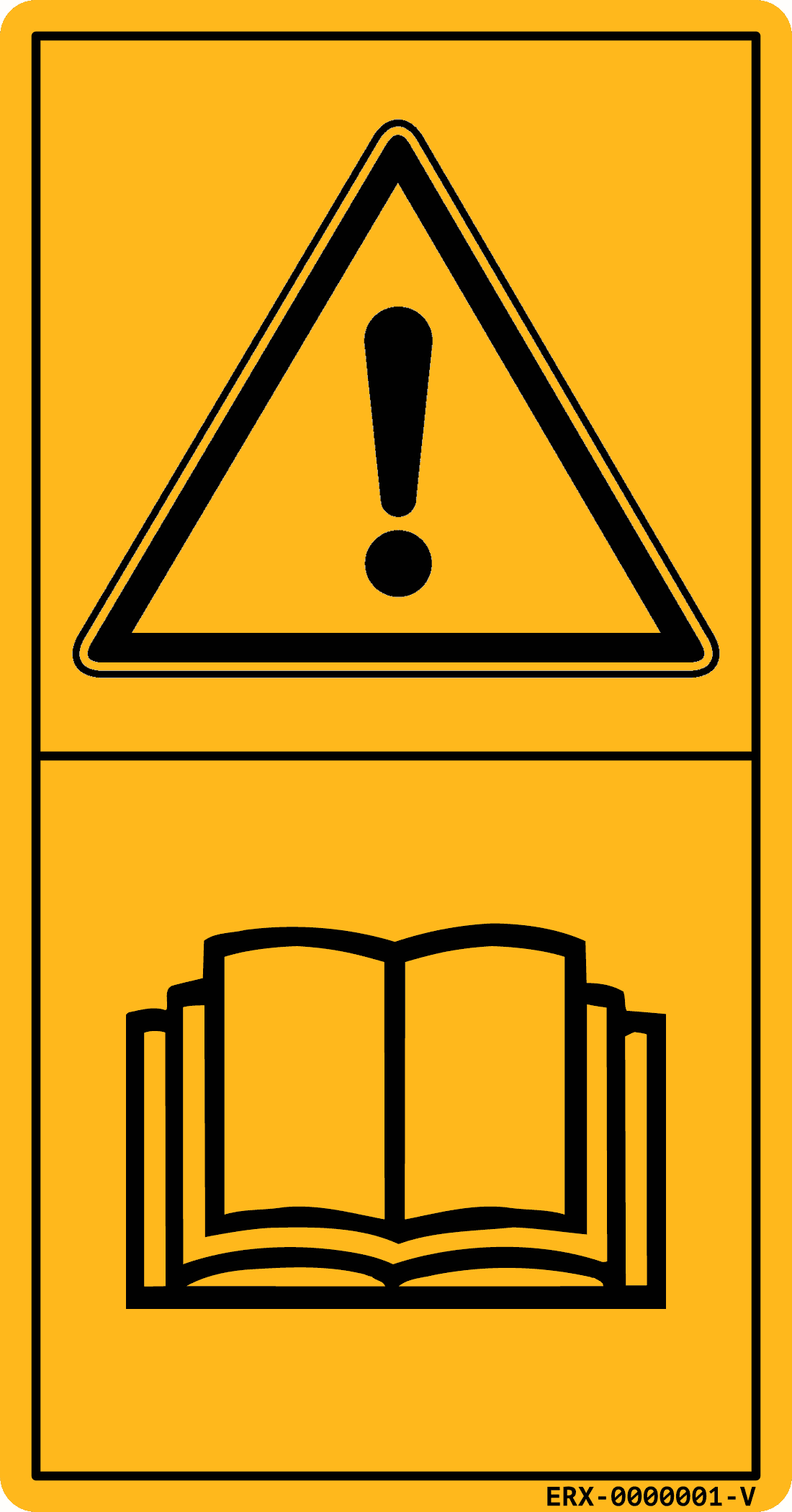

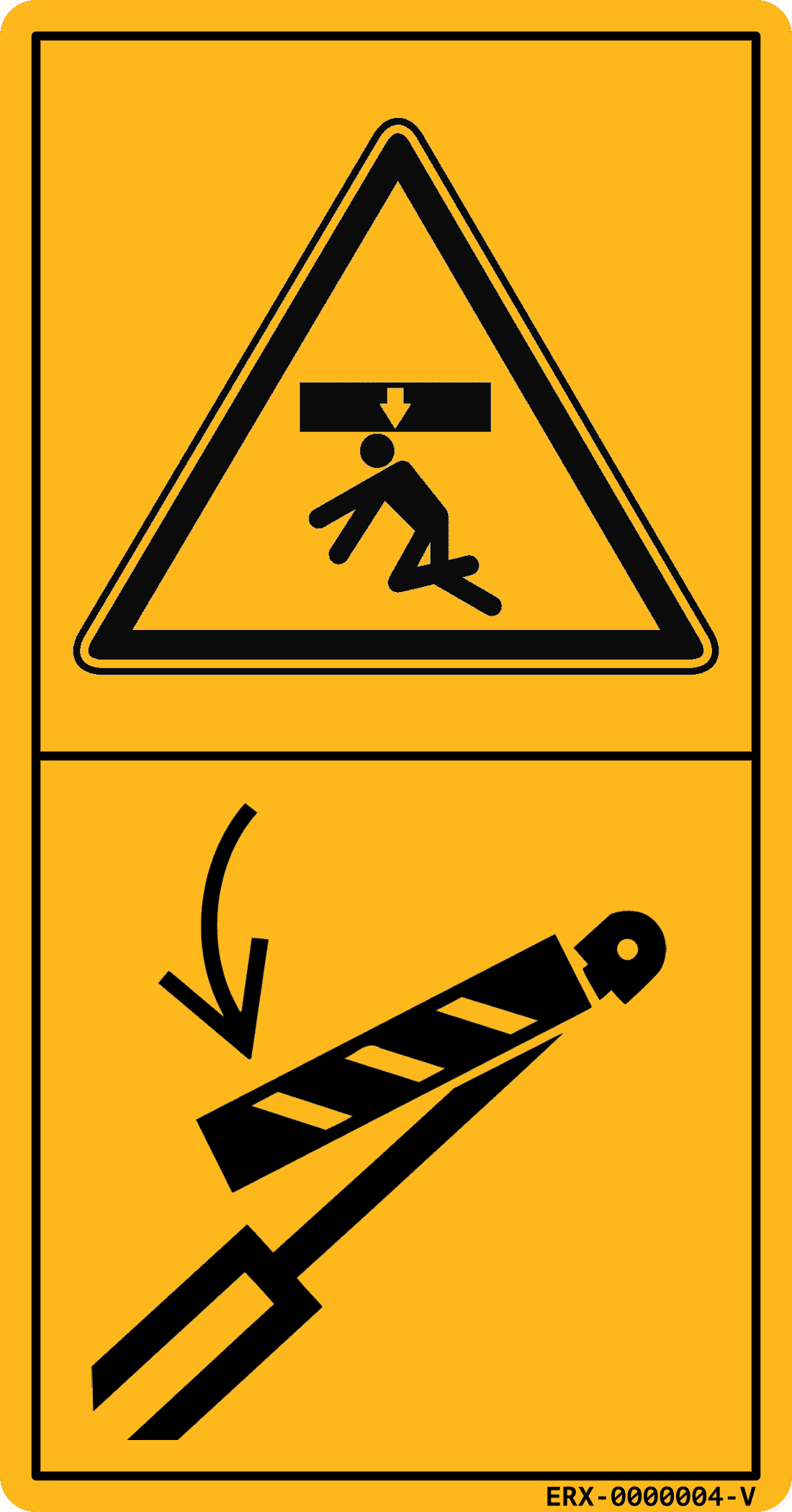

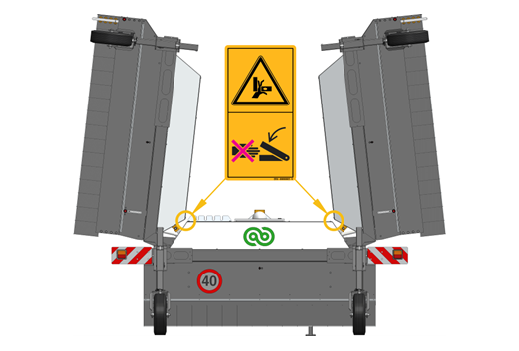

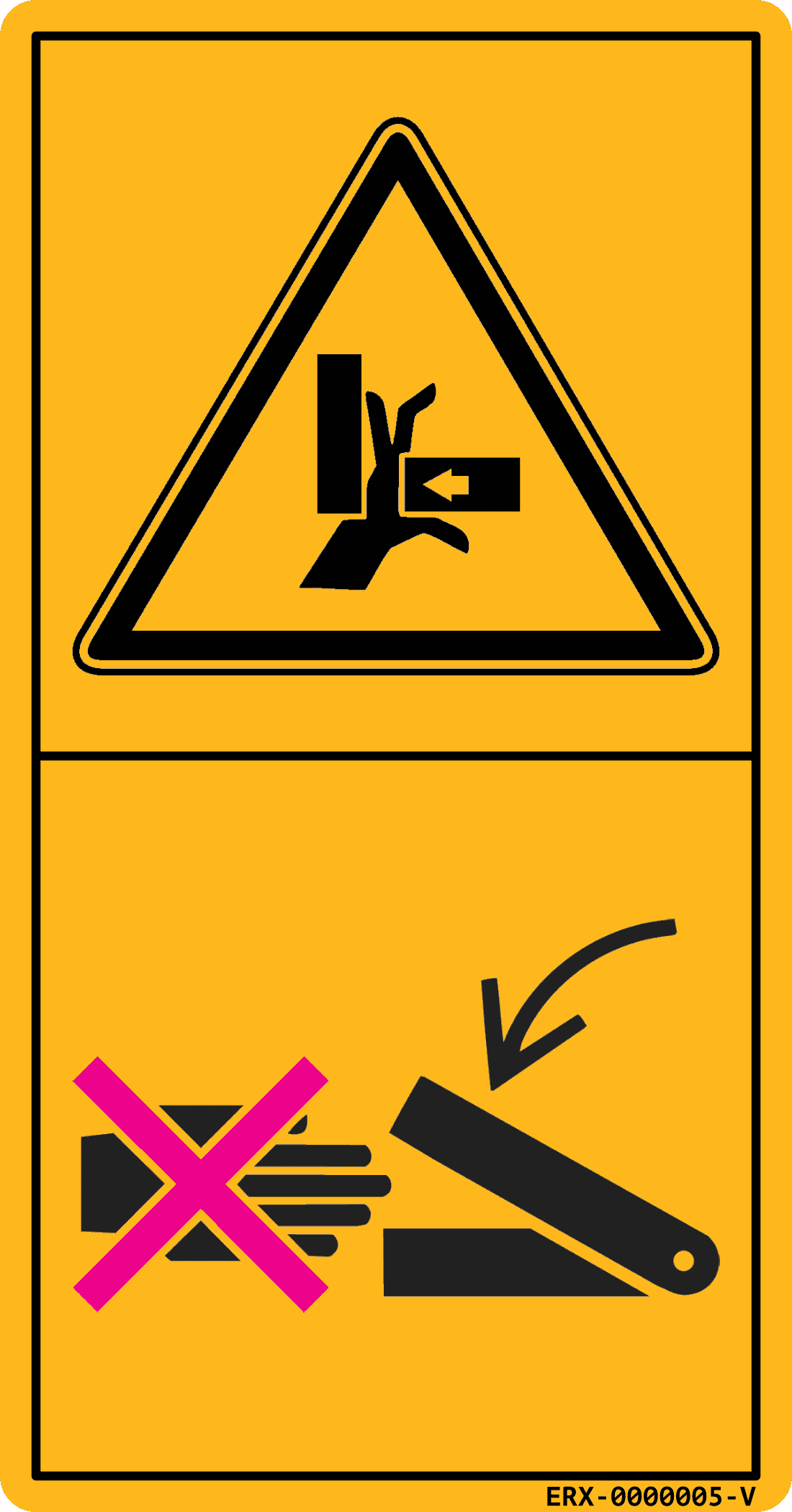

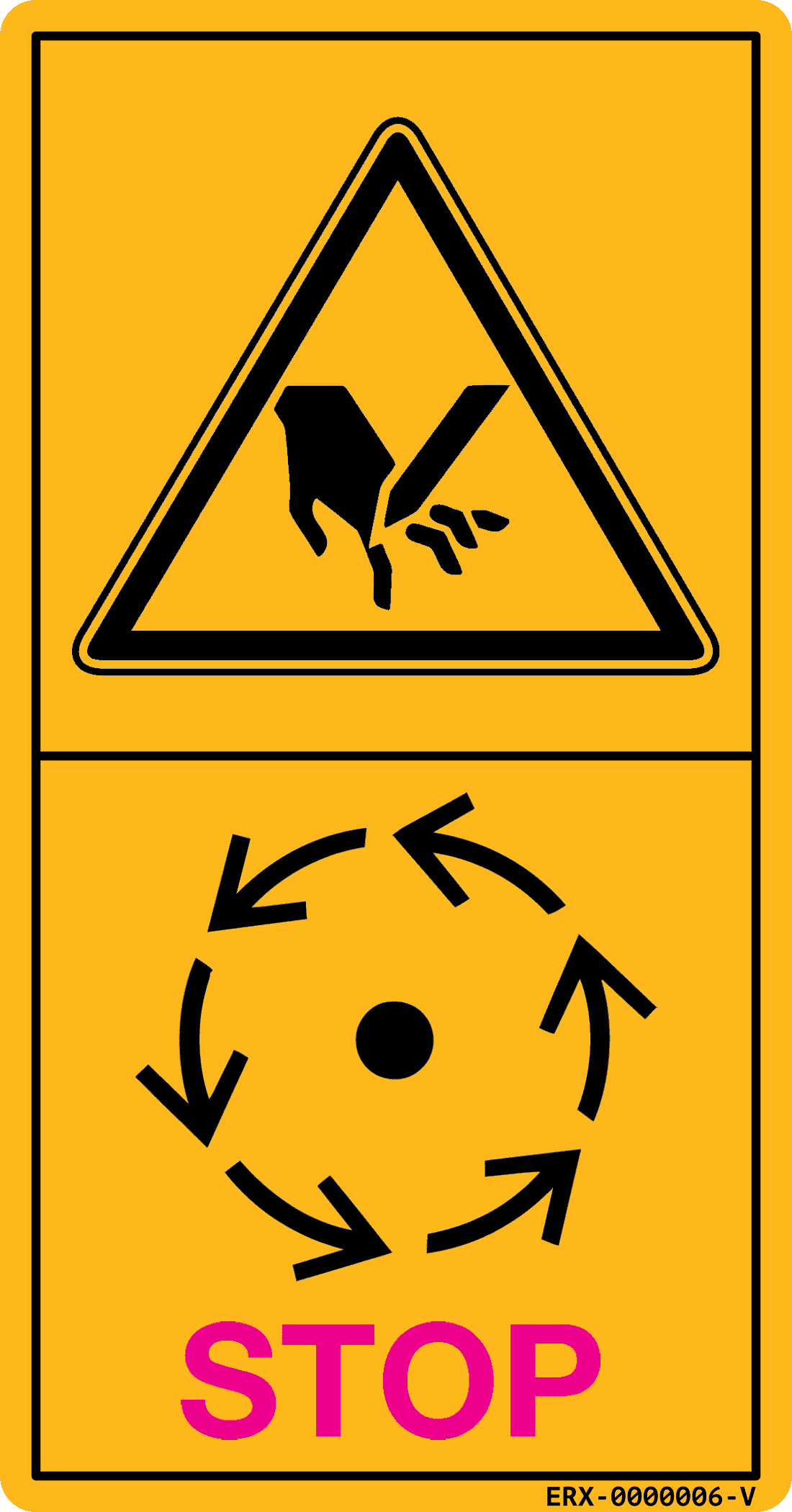

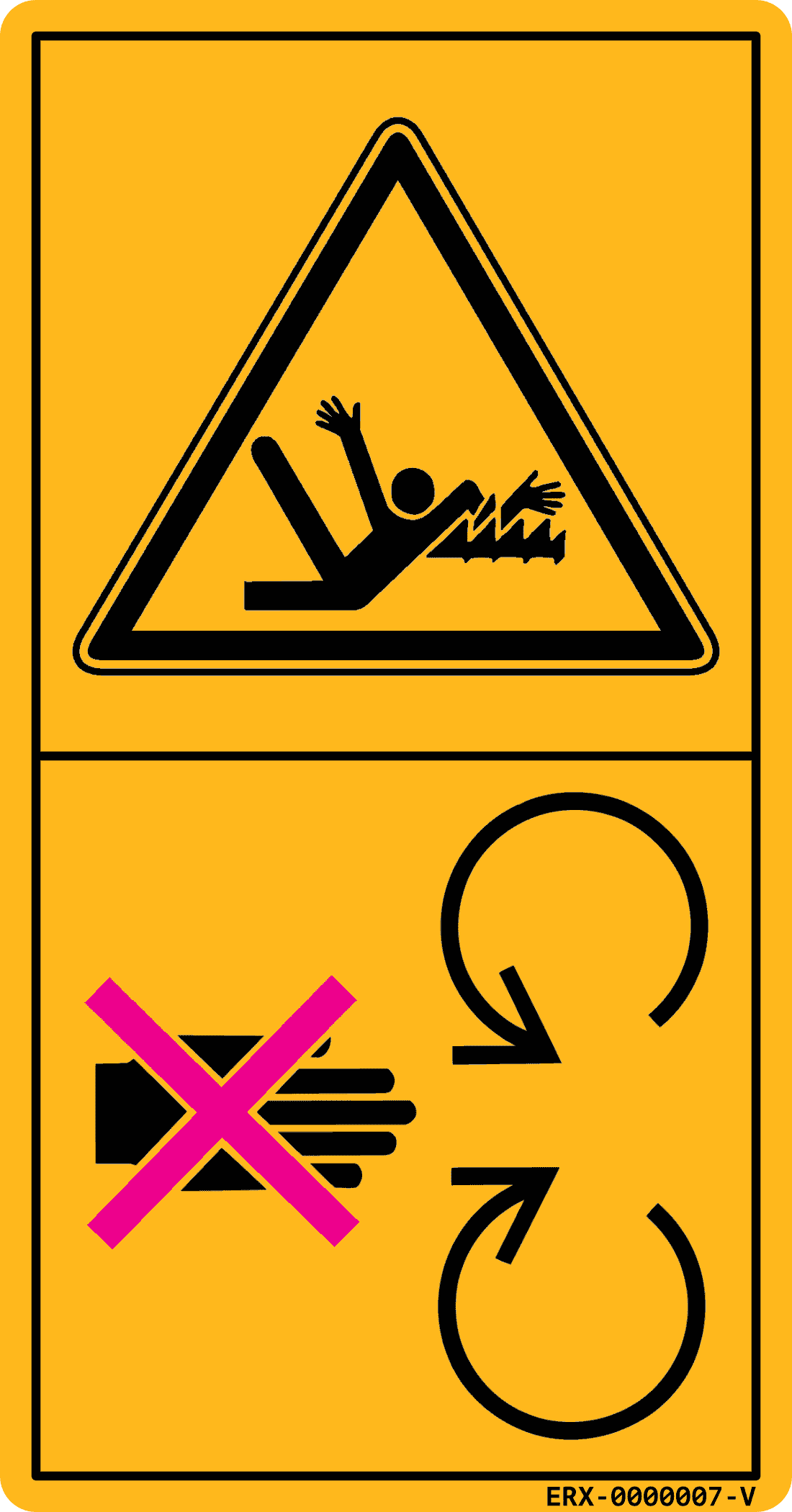

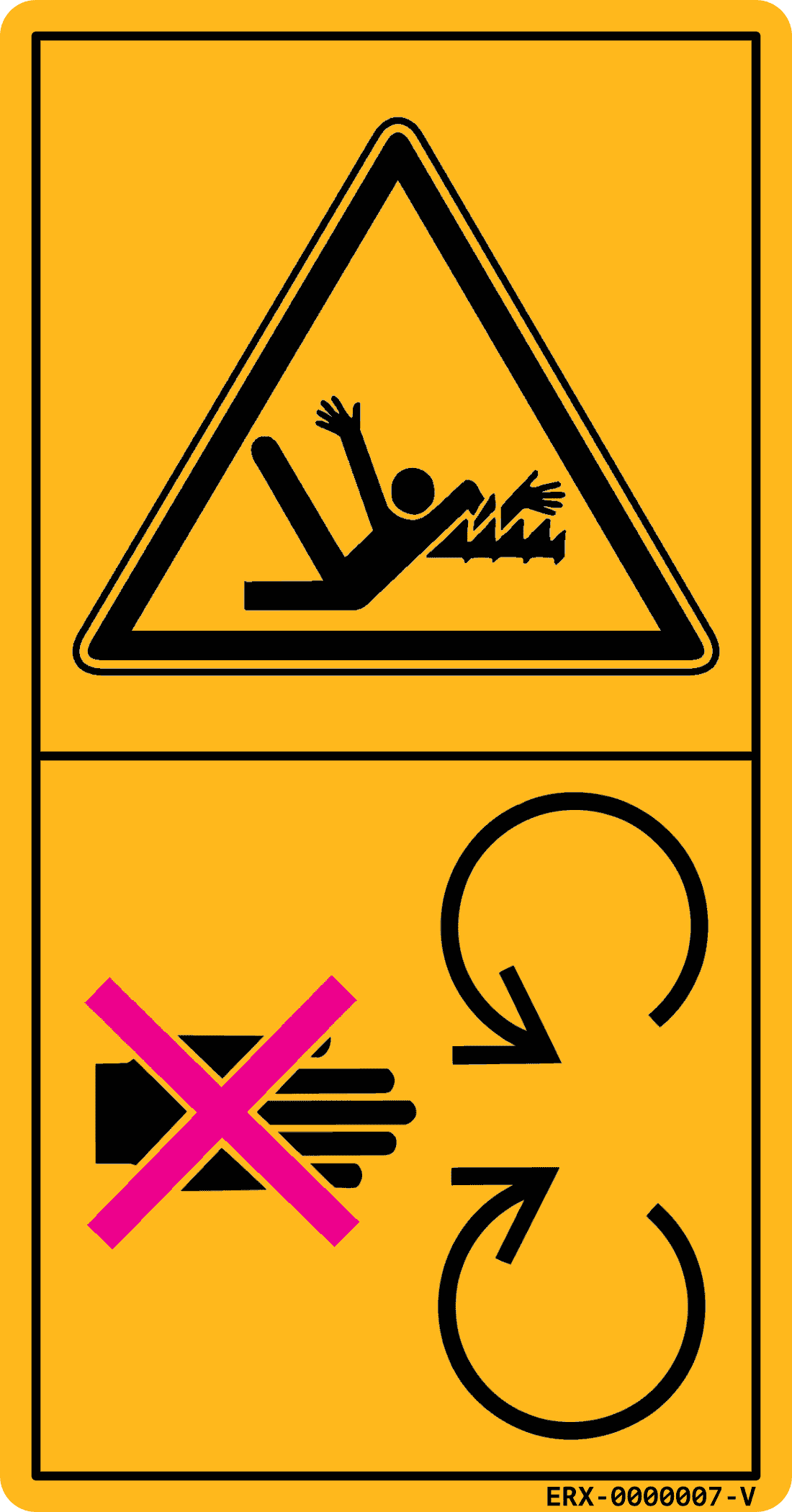

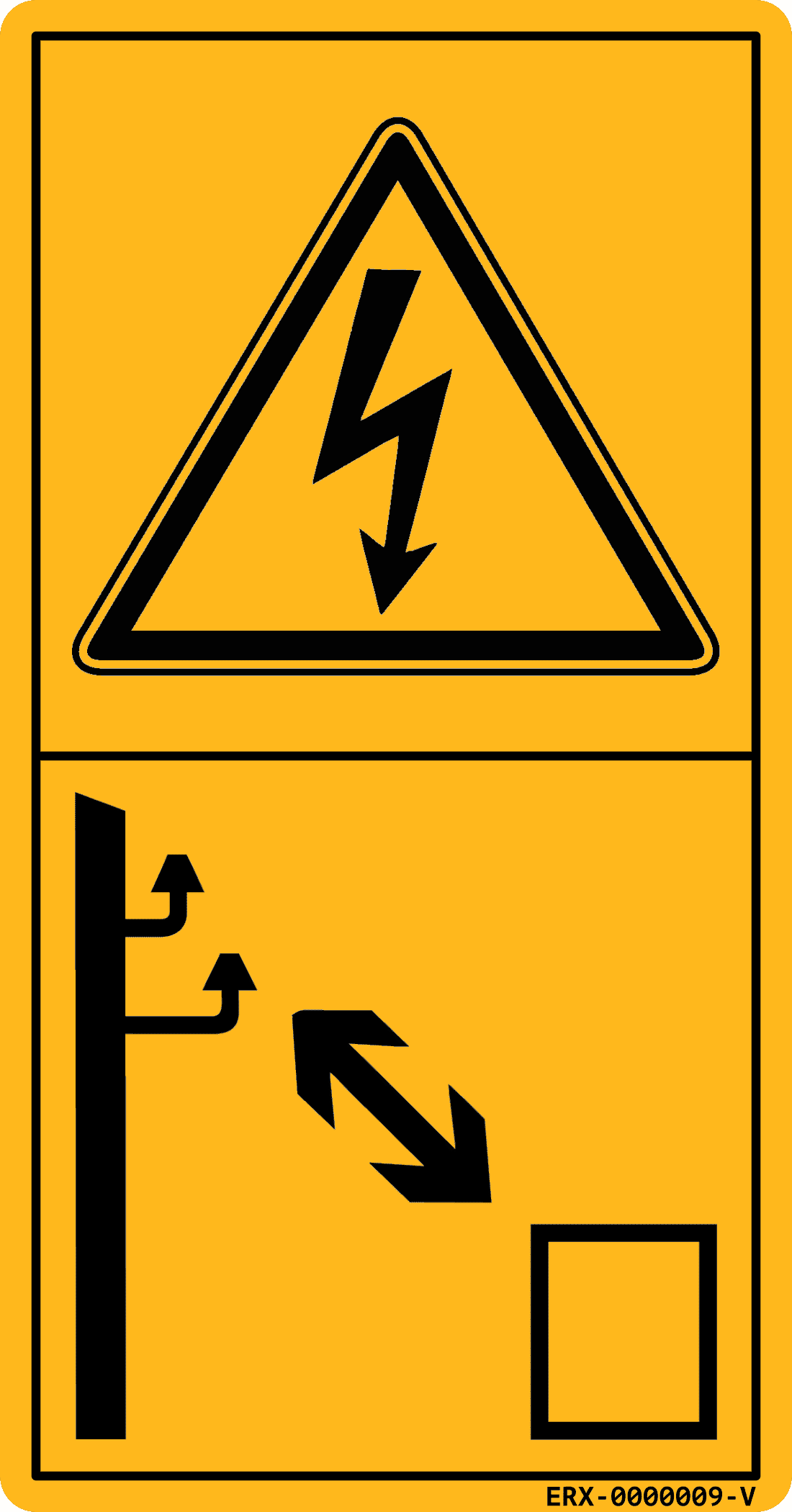

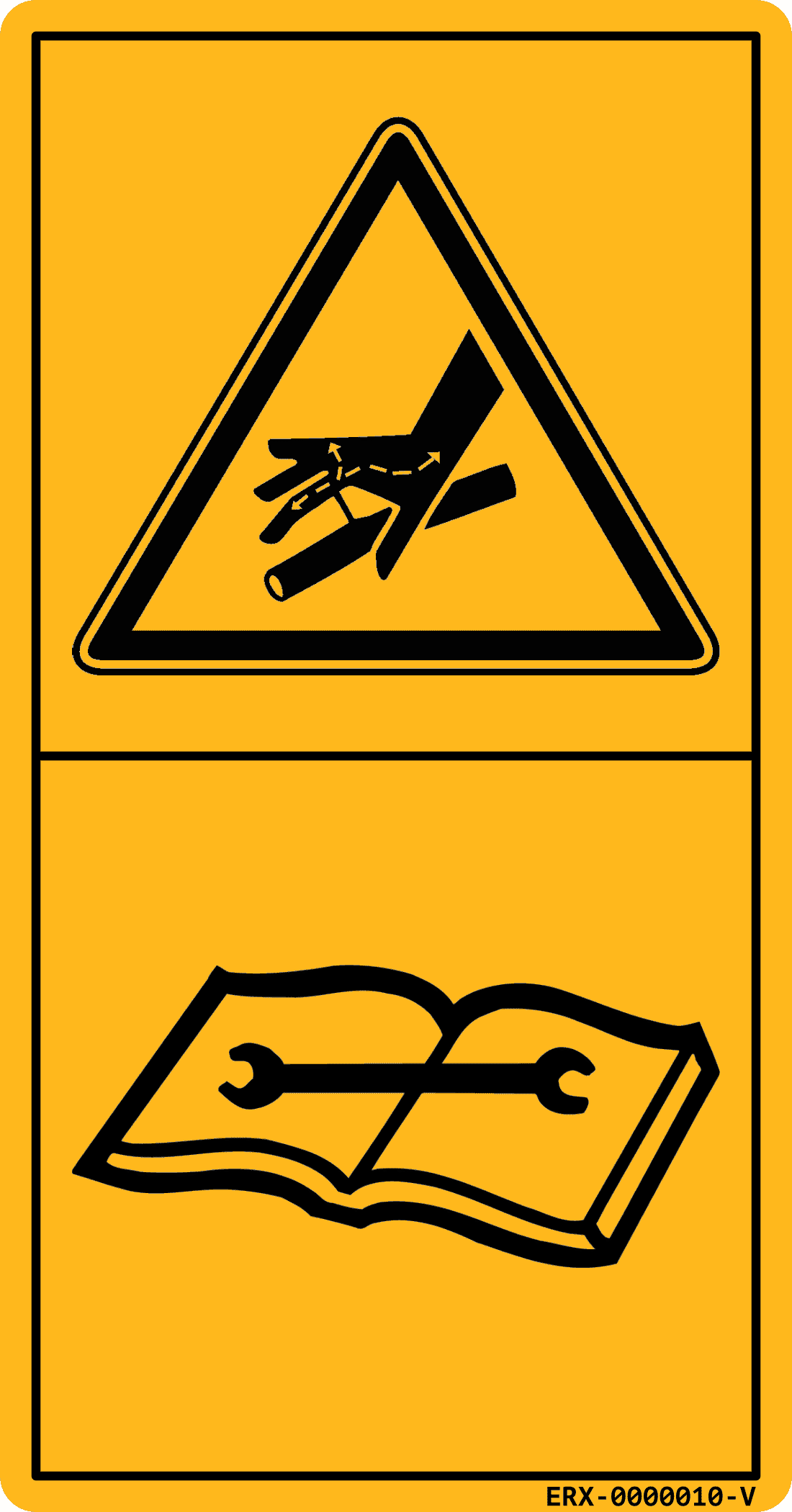

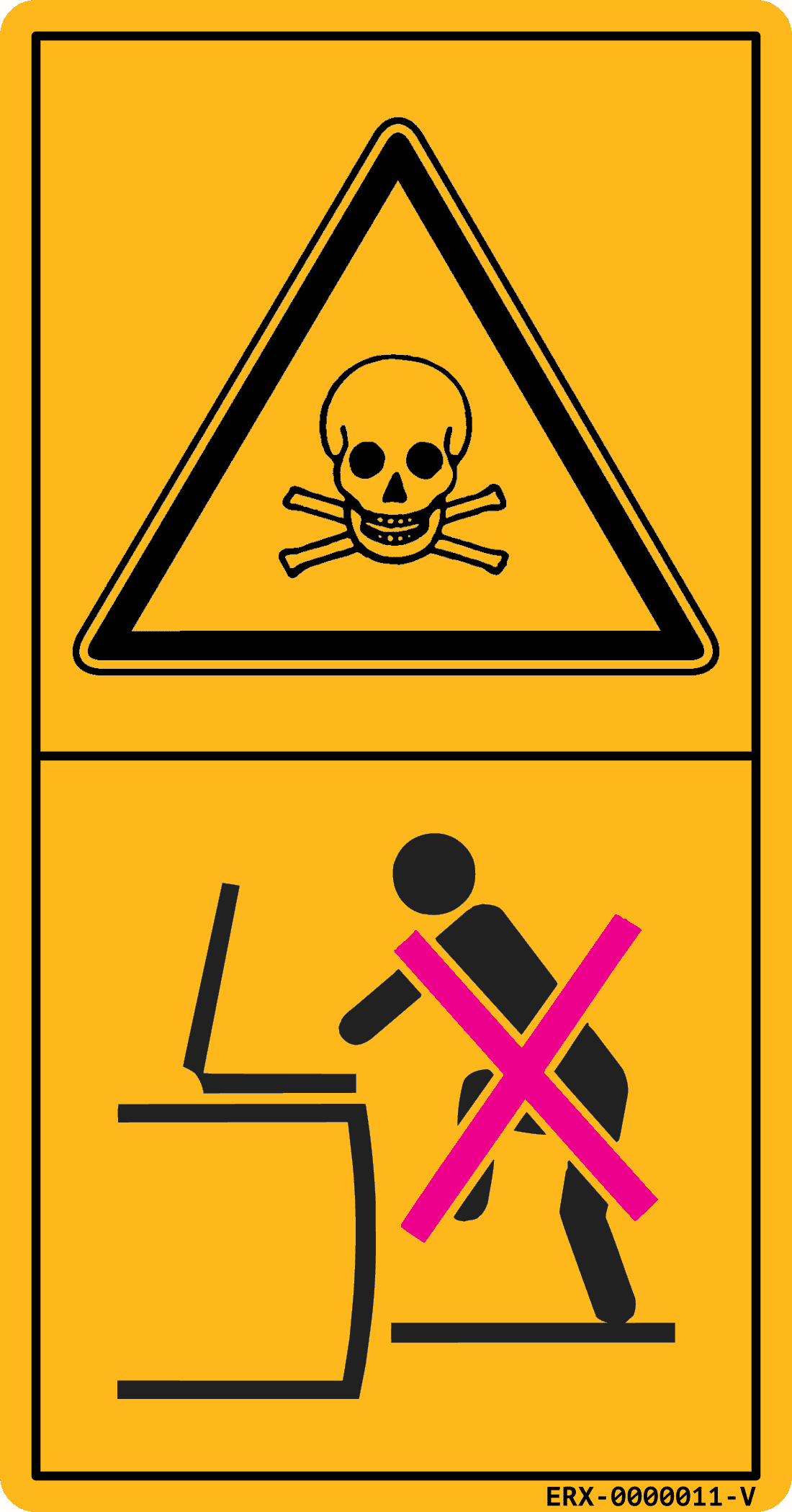

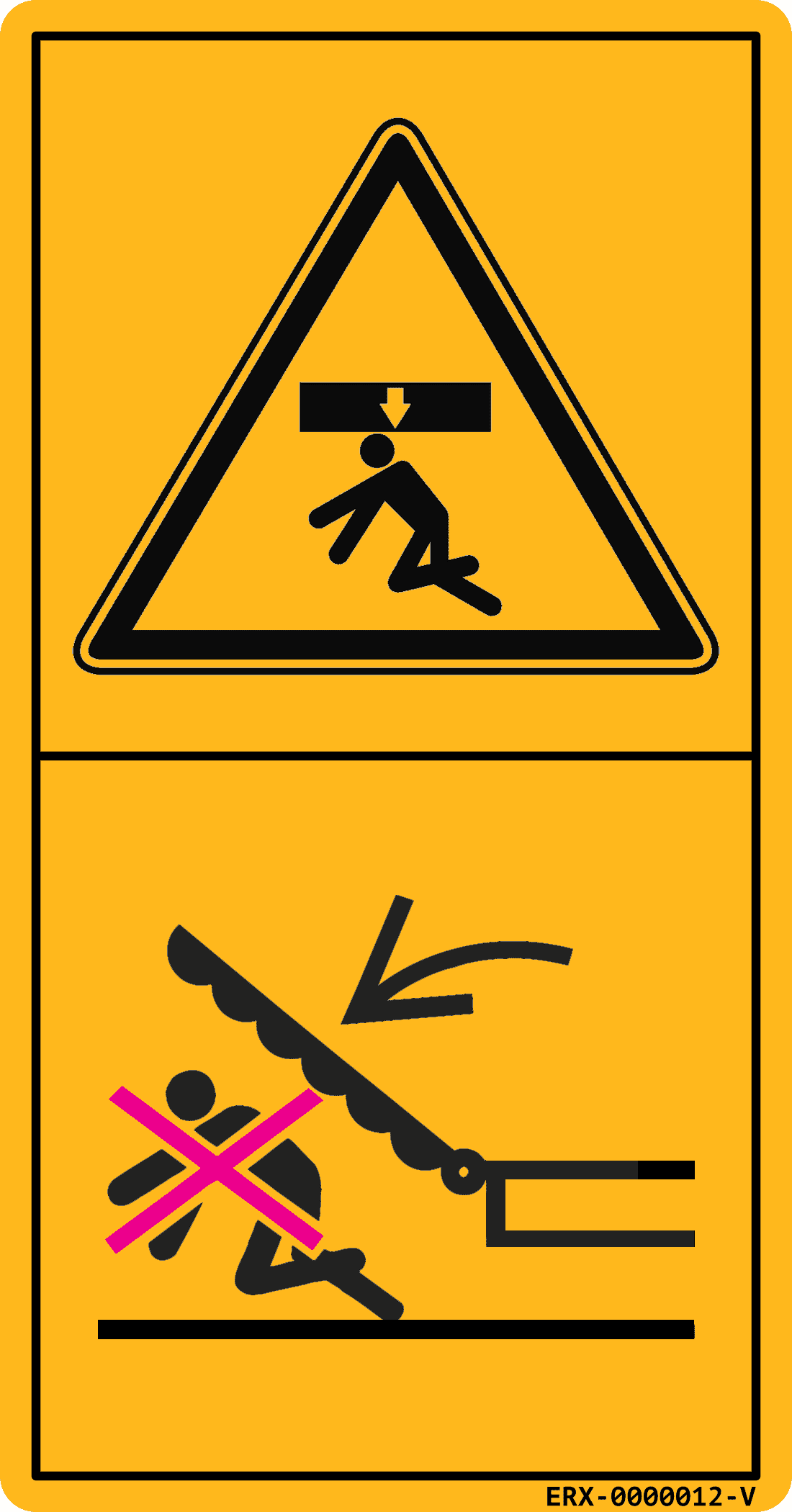

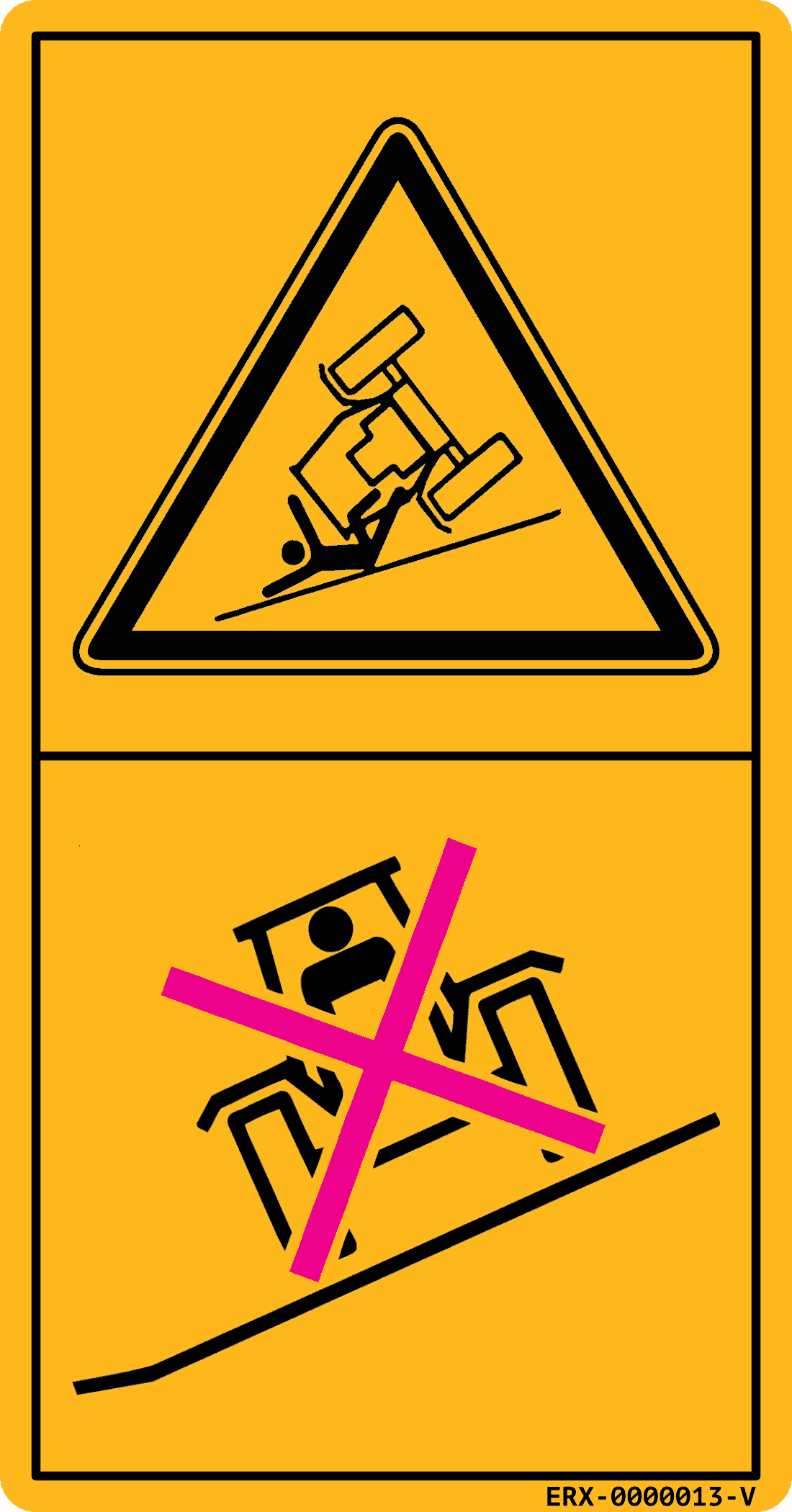

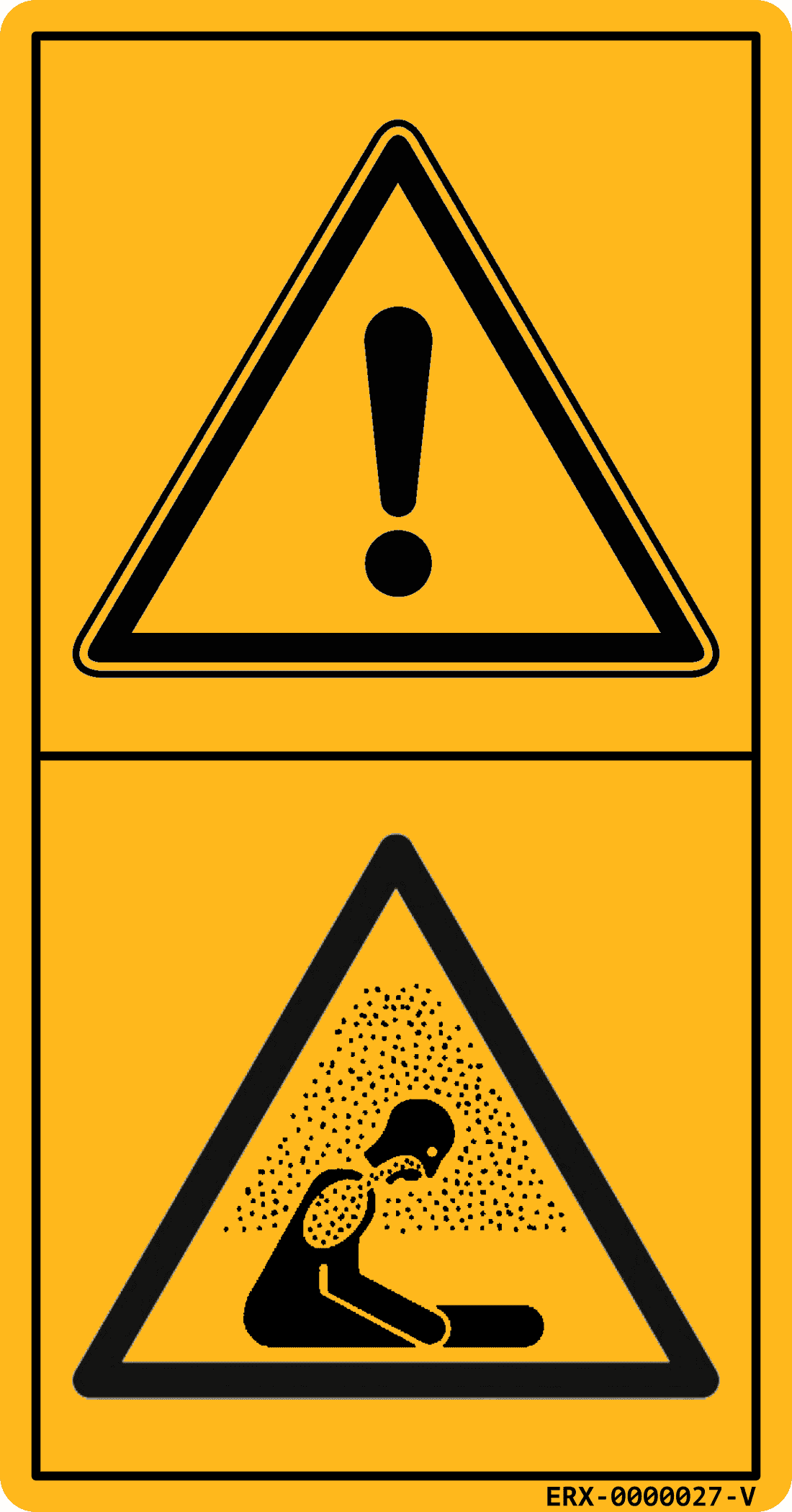

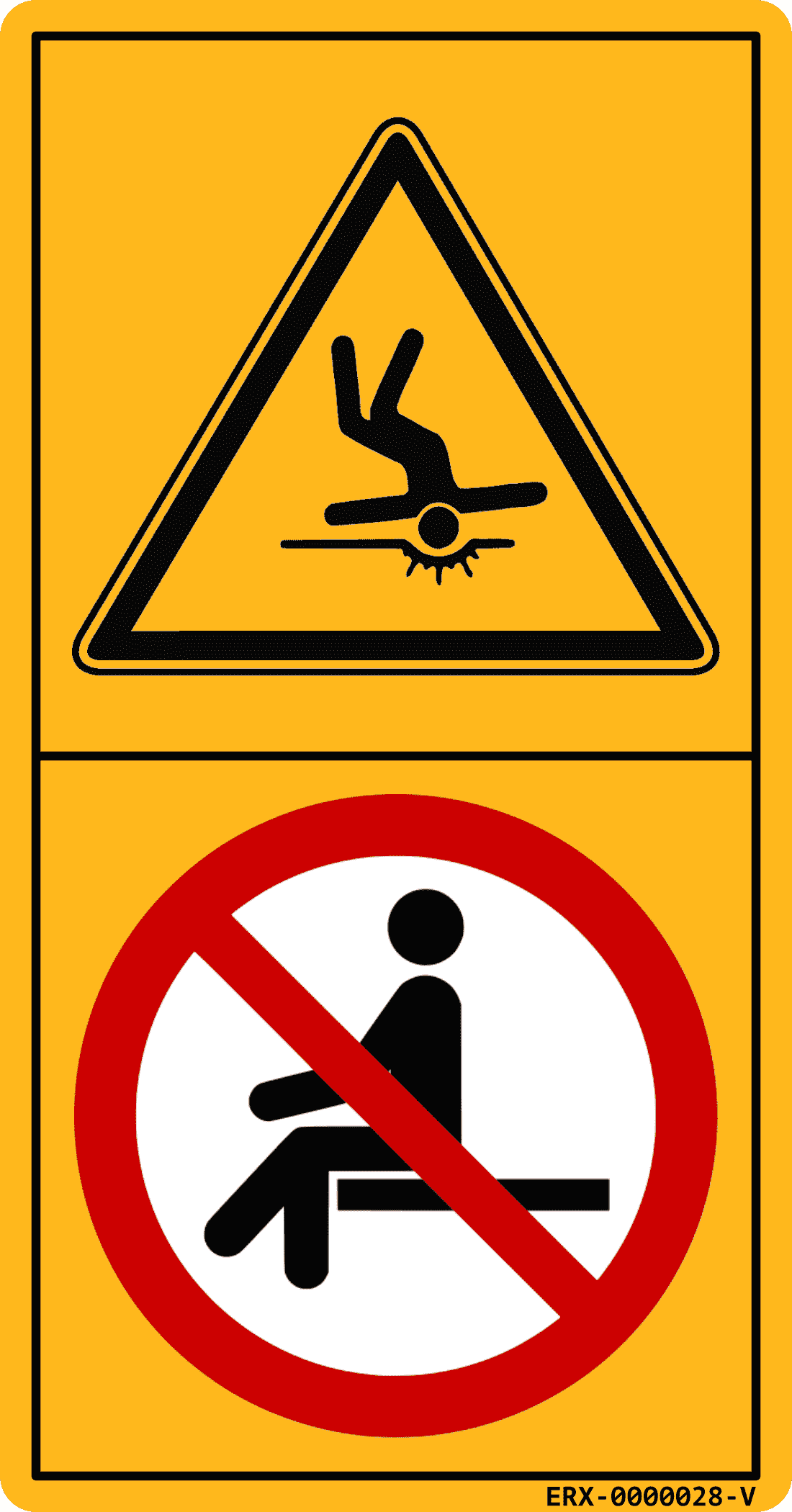

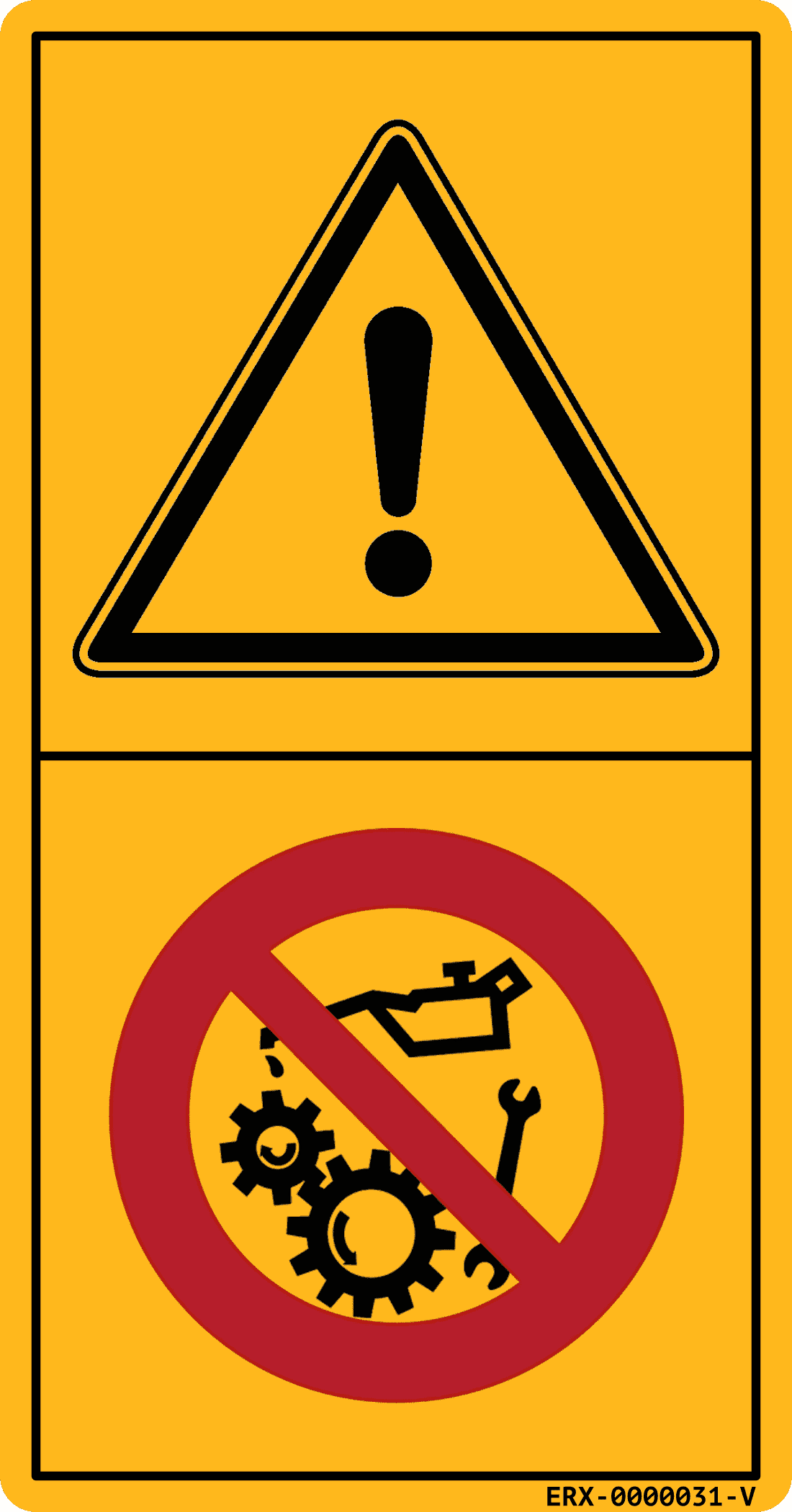

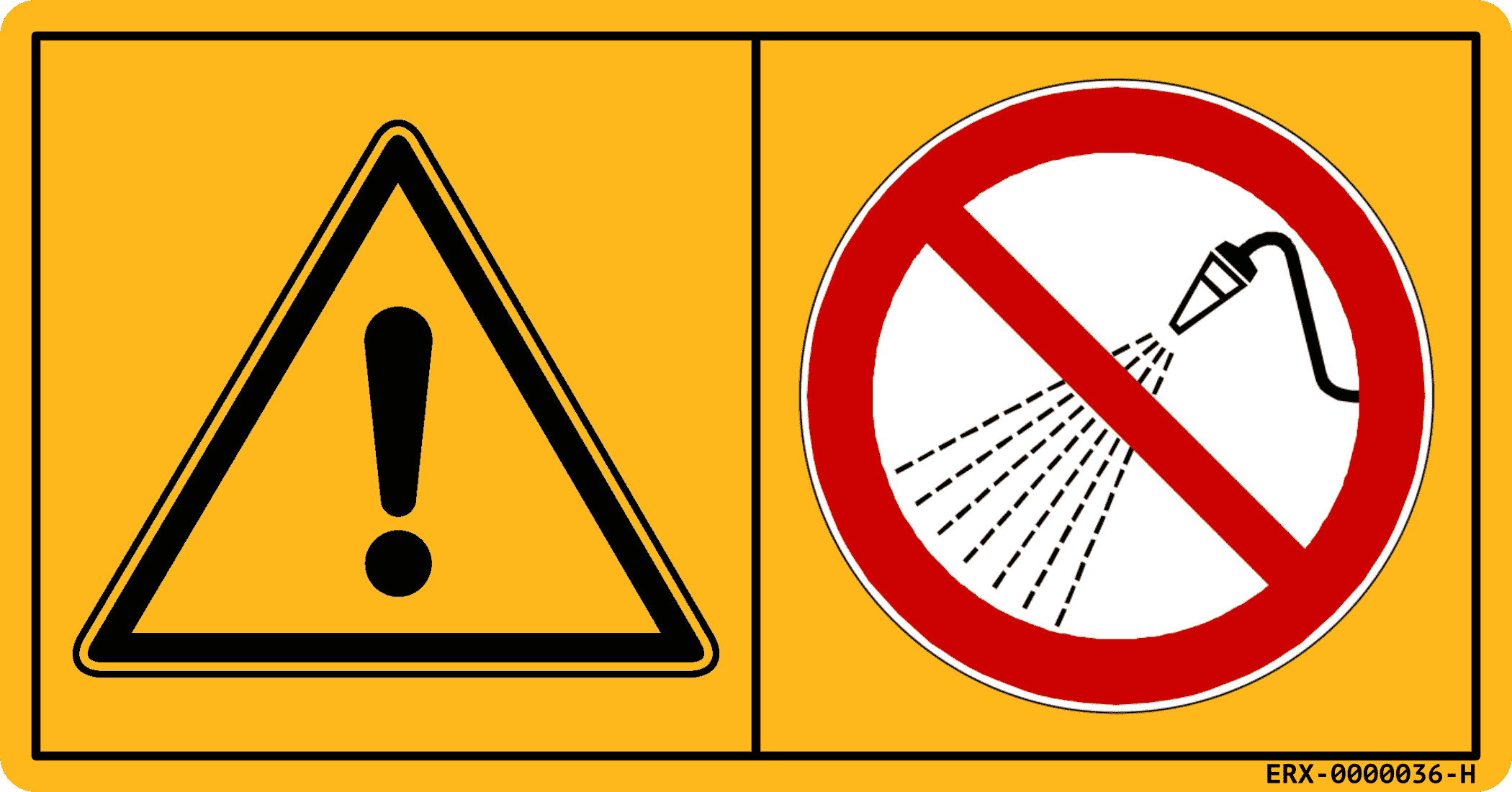

Pictograms

Pictograms informing of potential hazards as well as safety rules to be followed are placed at various locations on the machine.

-

Ensure that these pictograms are always clean and legible.

-

If they are damaged, worn or missing, replace them according to their type and position on the machine as indicated in this manual.

Read and follow the instructions

-

Before using the machine:

-

Read and understand all safety instructions in this manual.

-

Read the warnings on the machine.

-

Familiarize yourself with the operation of the machine and its various controls.

-

-

Never entrust the machine to an untrained person.

-

Contact your Ecorobotix dealer if any part of this manual is not completely understood.

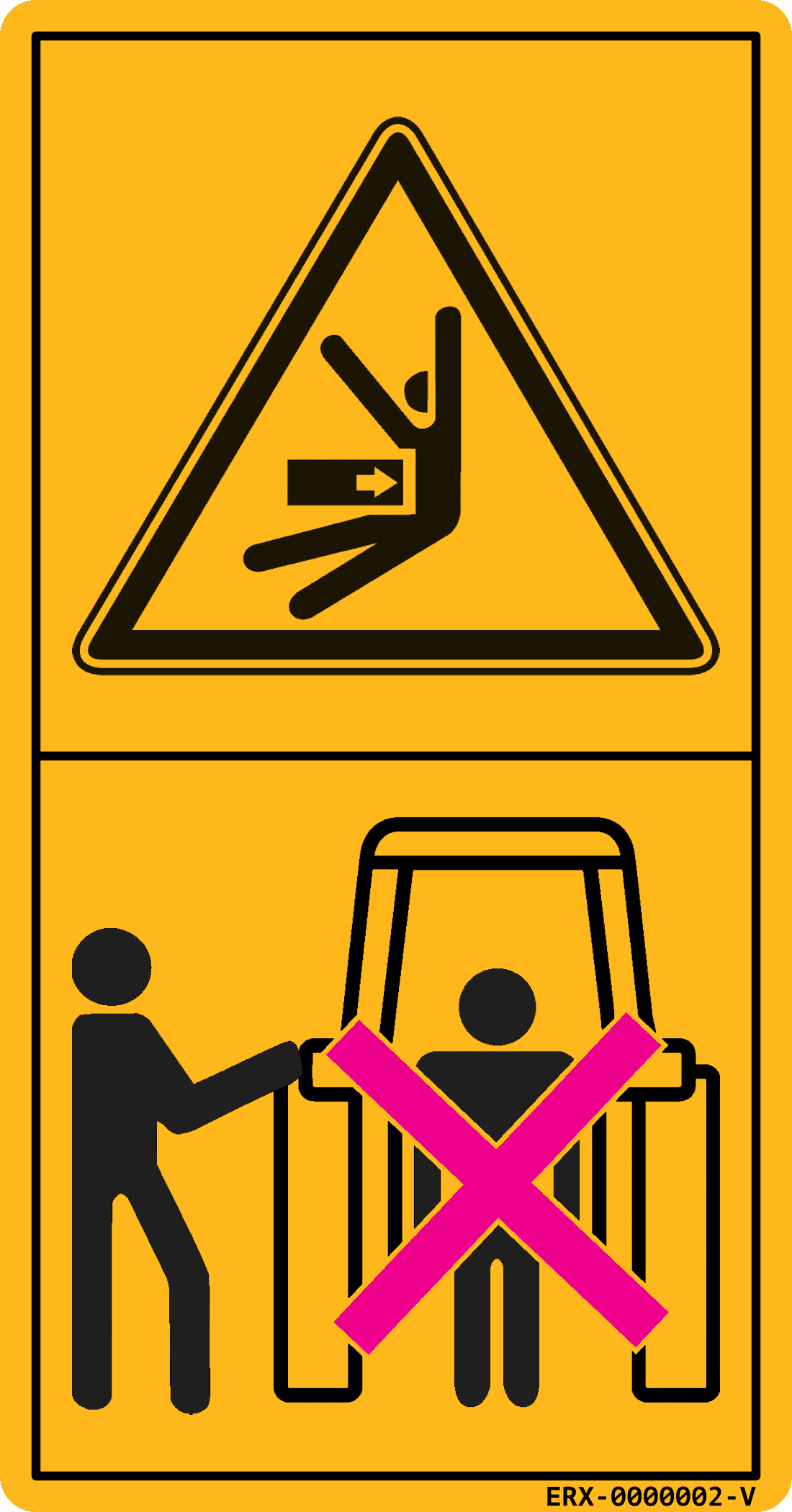

Hitching

-

Before hitching up the machine:

-

Check that the machine cannot move suddenly and unexpectedly.

-

If necessary, place chocks under the wheels.

-

-

Only use the coupling points provided for this purpose.

-

Do not stand between the lower coupling points of the machine or between the lower coupling points of the tractor when coupling.

-

Do not stand between the tractor and the machine when lifting the machine.

-

Before standing between the machine and the tractor, always apply the tractor’s parking brake and put the gearbox in neutral.

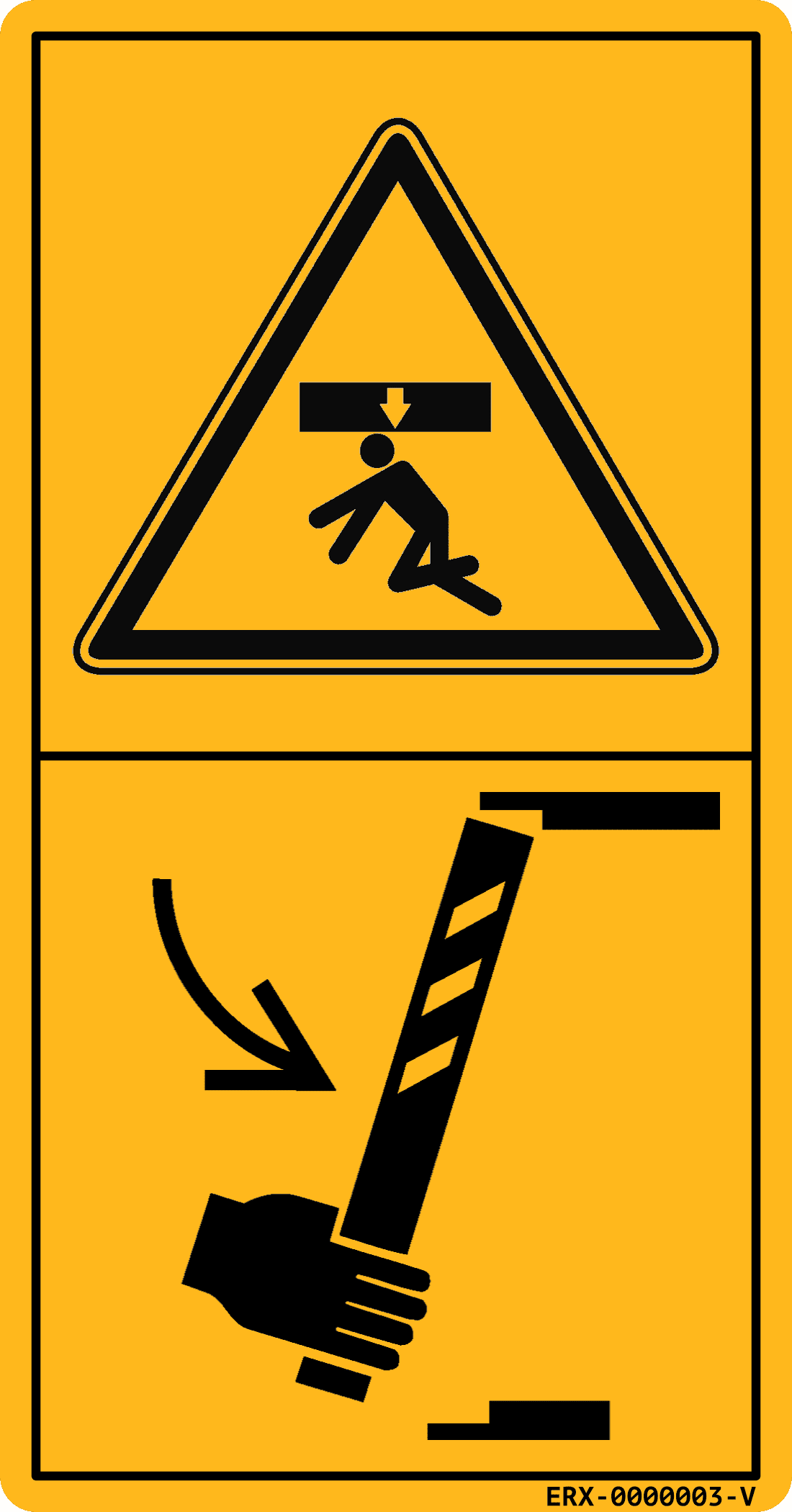

Parking supports

-

Parking supports must be raised when moving the machine.

-

They must be lowered before unhitching.

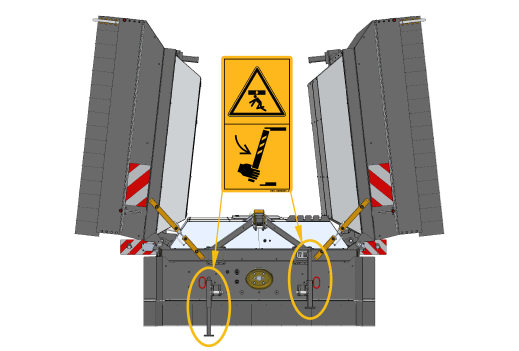

Handling of the lateral modules

-

Make sure that neither persons nor animal or objects are in the proximity of the machine.

-

Make sure that the modules will not touch any objects during movement.

-

Make sure the machine is properly attached to the three-point hitch.

-

Make sure that the safety hooks are present and functional before lifting or lowering the modules.

-

Make sure the modules are locked with the safety hooks when they are lifted.

-

Make sure that the safety hooks of the modules to be lowered are unlocked with their respective ropes.

WARNING

Never attempt to lower two modules with locked safety hooks.

INFORMATION

It is possible to lower only one module at a time if necessary.

Risk of crushing

Stay away from areas where there is a risk of crushing, especially when handling the modules.

Risks related to moving parts

Wait until all parts of the machine have come to a complete stop before working on it.

PTO drive shaft

-

Use only the cardan shafts supplied with the machine or recommended by the manufacturer.

-

Ensure that the following items are in place and in good condition:

-

The tractor PTO shield.

-

PTO shaft guards.

-

The machine’s input shaft guard.

-

-

Make sure that the PTO shaft guards are always secured against rotation by their safety chains.

-

Check that the guards can rotate freely one full revolution independently of the shaft.

-

Replace worn or damaged guards immediately. A damaged guard or unguarded PTO shaft can cause a serious or fatal accident.

-

Wear clothing that fits snugly around your body so that you will not be caught by a rotating PTO shaft.

-

Before connecting or disconnecting a PTO shaft or before working on the machine:

-

Disengage the PTO.

-

Turn off the tractor engine.

-

Remove the ignition key.

-

Wait until all moving parts have come to a complete stop.

-

-

If the primary PTO shaft is equipped with an overload clutch or freewheel, they must be mounted on the machine side.

-

Always ensure that the PTO shaft is correctly mounted and locked.

-

Before engaging the power take-off shaft, check that the selected frequency and direction of rotation of the power take-off shaft comply with the manufacturer’s specifications.

-

Before engaging the power take-off shaft, make sure that no persons or animals are in the vicinity of the machine. Never engage the PTO with the tractor engine off.

-

Do not install any adapter that overrides any part of the tractor’s PTO shield, PTO shaft, machine input shaft, or the adapter itself.

-

The tractor PTO shield must cover the end of the tractor PTO and the added adapter according to the table below.

-

When removing the machine, place the PTO shaft in the holder provided and cover the tractor PTO with the protective cap.

-

Read and observe the instructions in the manual supplied with the PTO shaft.

Before working on the machine

Before working on the machine:

-

Disengage the power take-off shaft.

-

Stop the tractor engine.

-

Remove the ignition key.

-

Wait until all moving parts have come to a complete stop.

-

Apply the tractor parking brake.

Power lines

-

General Safety:

-

Power lines are dangerous.

-

Arcing can occur at a distance, even without direct contact with the line.

-

Check that overhead power lines are sufficiently far away before handling the modules and during transport, especially if the machine is placed on a high trailer.

-

-

Check that the minimum safety distances are respected before any operation on the machine or before moving it:

-

The distance between the machine or the operator and the overhead line must always be equal to or greater than the legal requirements in the area where the machine is used.

-

Consider the geometry of the machine when lifting and lowering the modules.

-

-

When crossing railway tracks:

-

Ensure that the distance between the machine and the overhead line is at least 1.5 m | 4.9 ft.

-

Consider the irregularities of the ground.

-

Be extra careful in humid air.

-

Consider the additional height if the machine is on a trailer.

-

-

If the machine comes into contact with an overhead power line:

-

Notify emergency response services and comply with their instructions.

-

If the operator is in the tractor, remain in the tractor until the emergency response services allow the operator to leave.

-

If the operator is outside the tractor, he should move away from the tractor but keep a distance that allows him to maintain visual control of the situation, secure the area and warn others of the danger.

-

The return to normal use of the machine must be authorized by the emergency services.

-

Hydraulic system

-

Basic hydraulic safety:

-

The working pressure of the hydraulic system is 200 bar | 2900 psi.

-

Pressurized oil in the hydraulic system can puncture the skin and cause serious injury.

-

In case of injury, seek medical attention promptly, as there is a risk of infection.

-

-

Before working on the hydraulic system:

-

Lower the machine to the ground with the two modules unfolded.

-

Depressurize the system.

-

Stop the tractor engine.

-

Remove the ignition key.

-

Wait until all moving parts have come to a complete stop.

-

-

Before connecting a hose to the tractor’s hydraulic system:

-

Make sure the system on the tractor side is not pressurized.

-

-

Before disconnecting a hose:

-

Depressurize the hydraulic system.

-

-

To prevent incorrect connection:

-

Put a coloured identification mark on the hydraulic couplings and the corresponding hoses.

-

Reversing the functions (e.g. raising or lowering) can lead to a risk of personal injury.

-

-

Hose maintenance:

-

Regularly visually inspect hydraulic hoses for wear or damage.

-

Replace them every 5 years.

-

Replace immediately if worn or damaged.

-

Use only replacement hoses of the specifications and quality specified by the machine manufacturer.

-

-

Locating leaks:

-

Use appropriate means.

-

Protect body and hands from pressurized fluid.

-

Risk of poisoning

-

Never enter the tank.

-

Never stir liquids with your hands.

-

All liquids on the machine are non-drinkable.

Risk of crushing

Stay away from the tipping area of the modules when handling them.

Travel and parking

-

Consider the conditions of adhesion according to the weight of the machine of the state of the ground or the road. These parameters can influence the precision of the steering, the grip of the tractor, the road holding and the efficiency of the braking devices. Follow the rules of caution dictated by each situation.

-

Adapt speed and driving style to the terrain, roads, and paths. Avoid abrupt changes in direction.

-

Consider the overhang, bulk and weight of the machine when turning. Use the side vision mirrors before entering a curve.

-

Never operate tractors on rough or sloping ground.

-

Never leave the operator’s position while the tractor is in motion.

-

Never raise or lower the side modules when the machine is perpendicular to the direction of the slope, as the jerks could cause the machine to tip over.

Parking without tractor

Parking without a tractor must only be carried out under the conditions described in the Kinematic and dynamic limits chapter (Kinematic and dynamic limits).

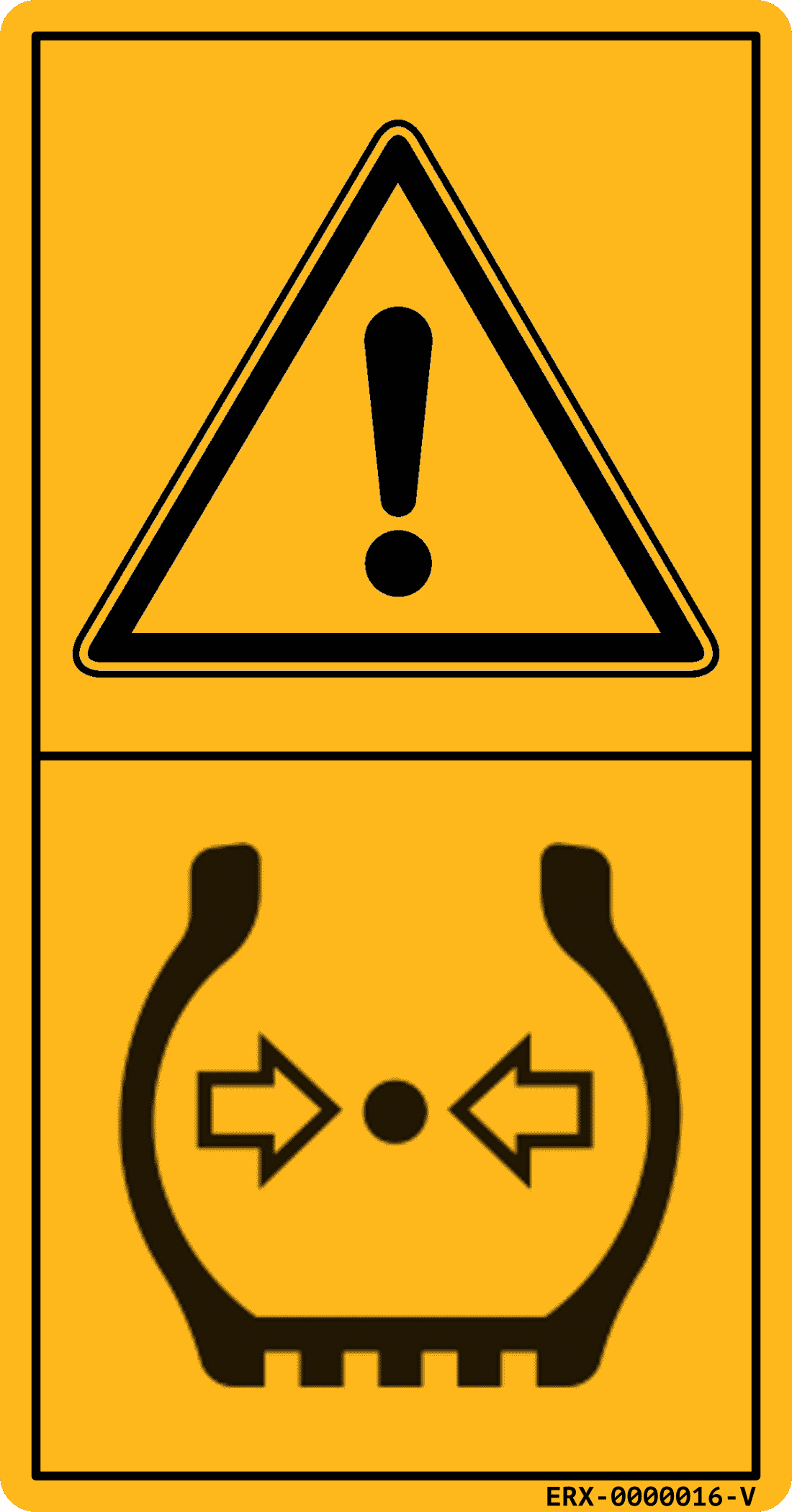

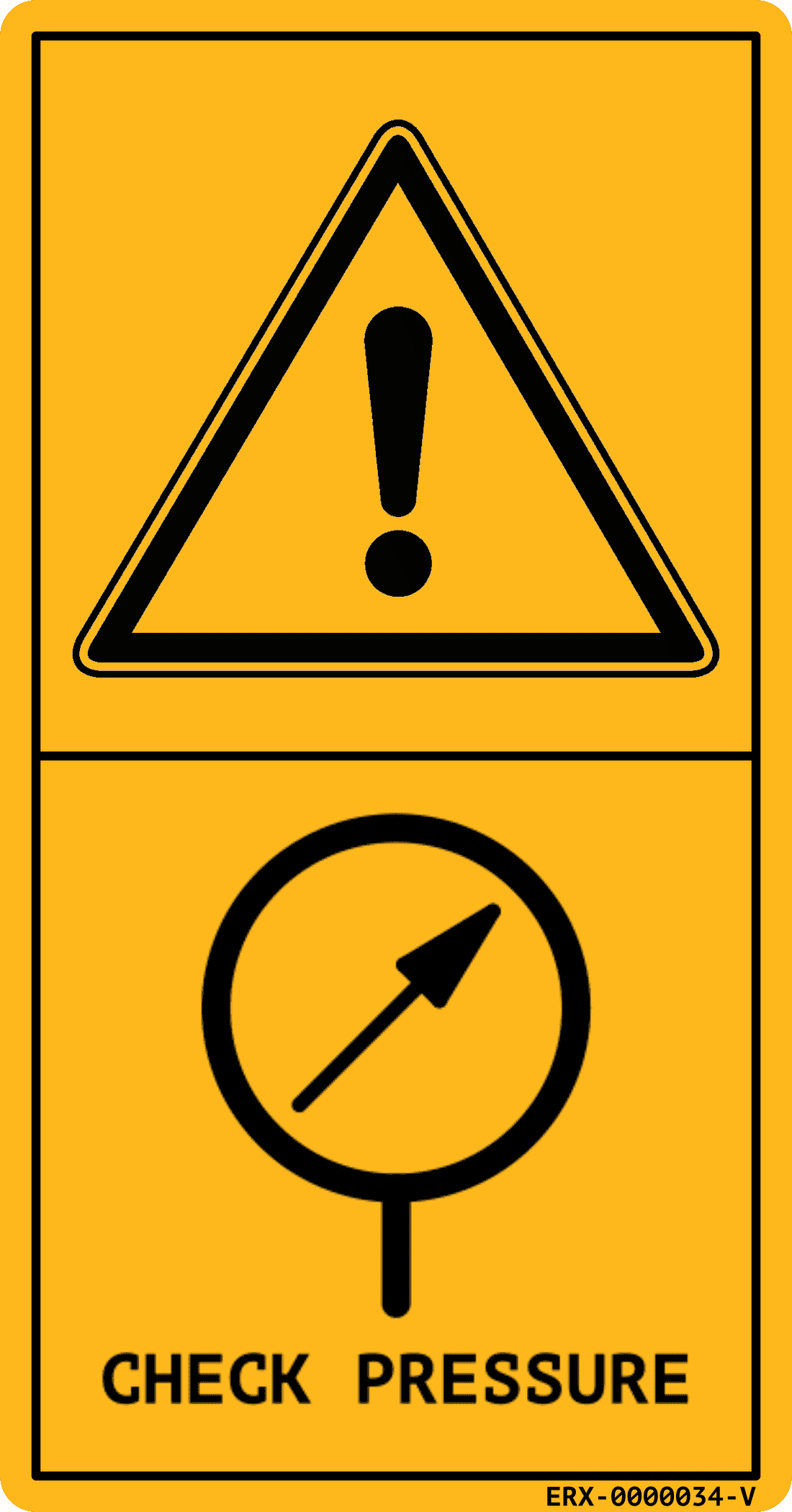

Tires

-

Check the tire pressure of the machine and the tractor regularly.

-

Observe the pressure specified by the manufacturer.

-

Tire changes must be carried out by qualified personnel.

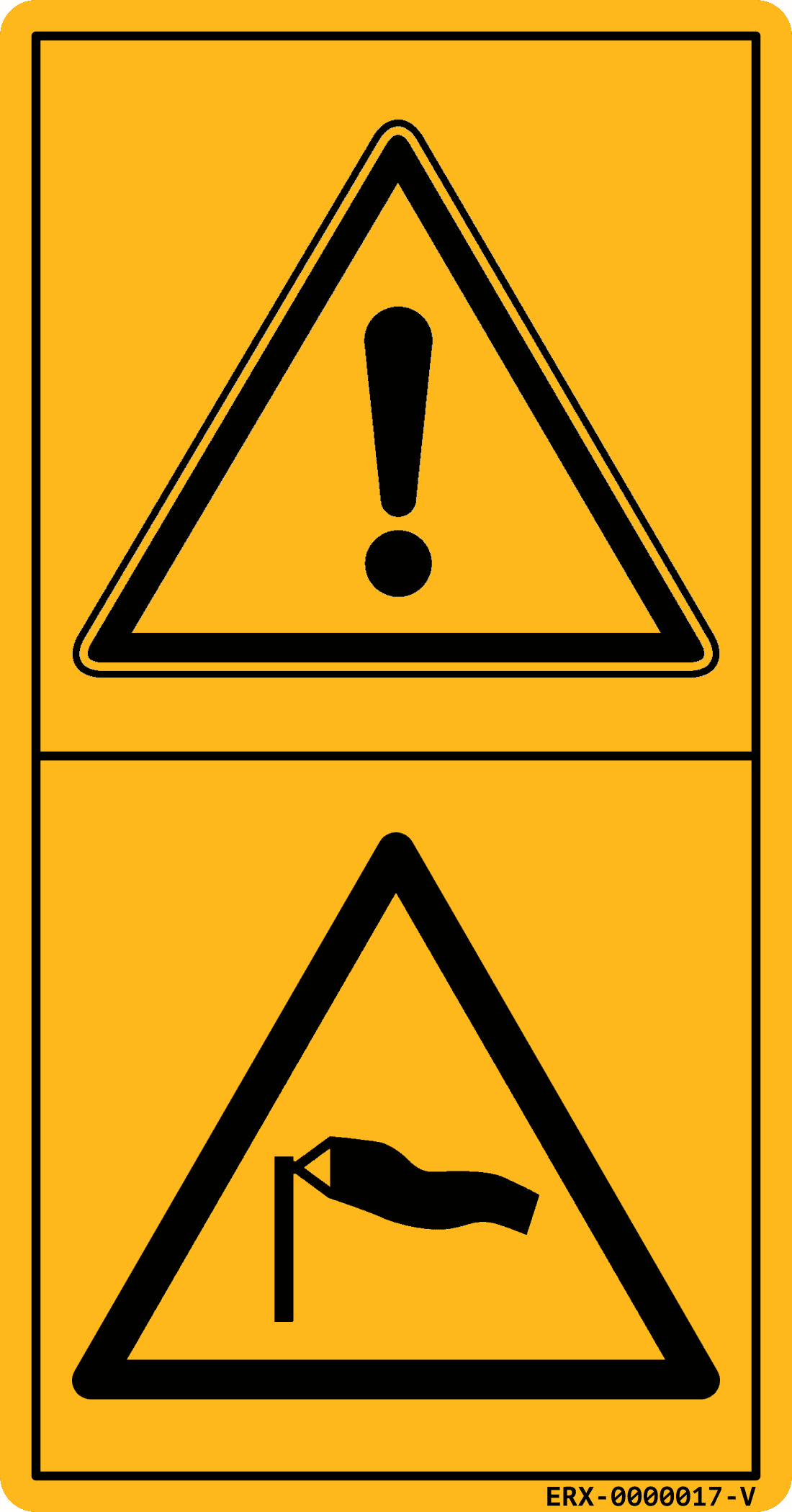

Wind conditions and clearing the spray area

-

Do not spray if wind speeds are greater than 4mph or if there are bystanders in the spray area.

-

Clear the work area of all bystanders and pets.

-

Restrict access to the area by the public for the period recommended on the chemical label.

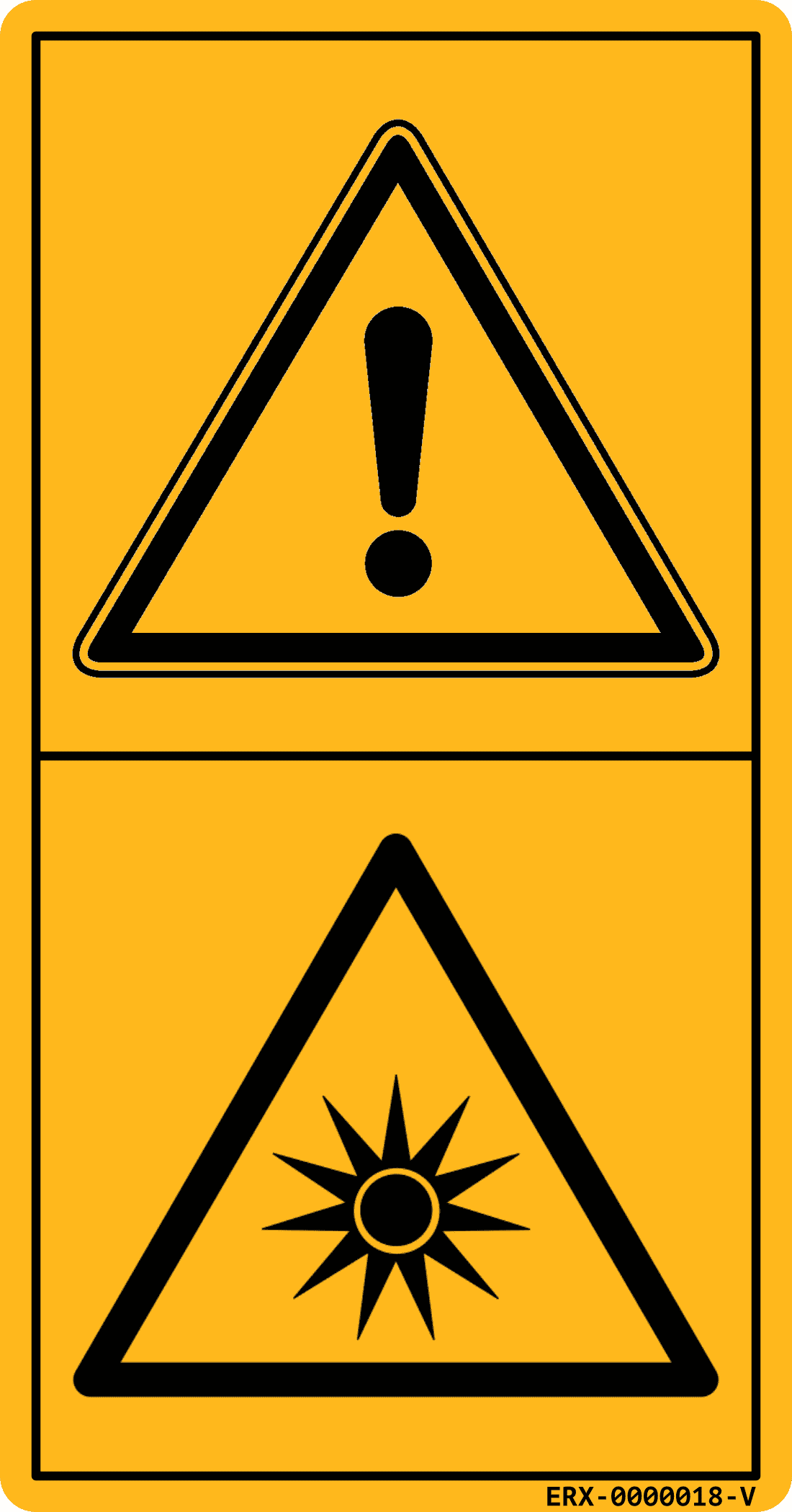

Strobe light

-

Keep sensitive people away.

-

Risk of epilepsy.

-

Risk of disturbance for the wildlife.

Wearing of PPE

Wear the PPE indicated on the pictogram when the situation requires it.

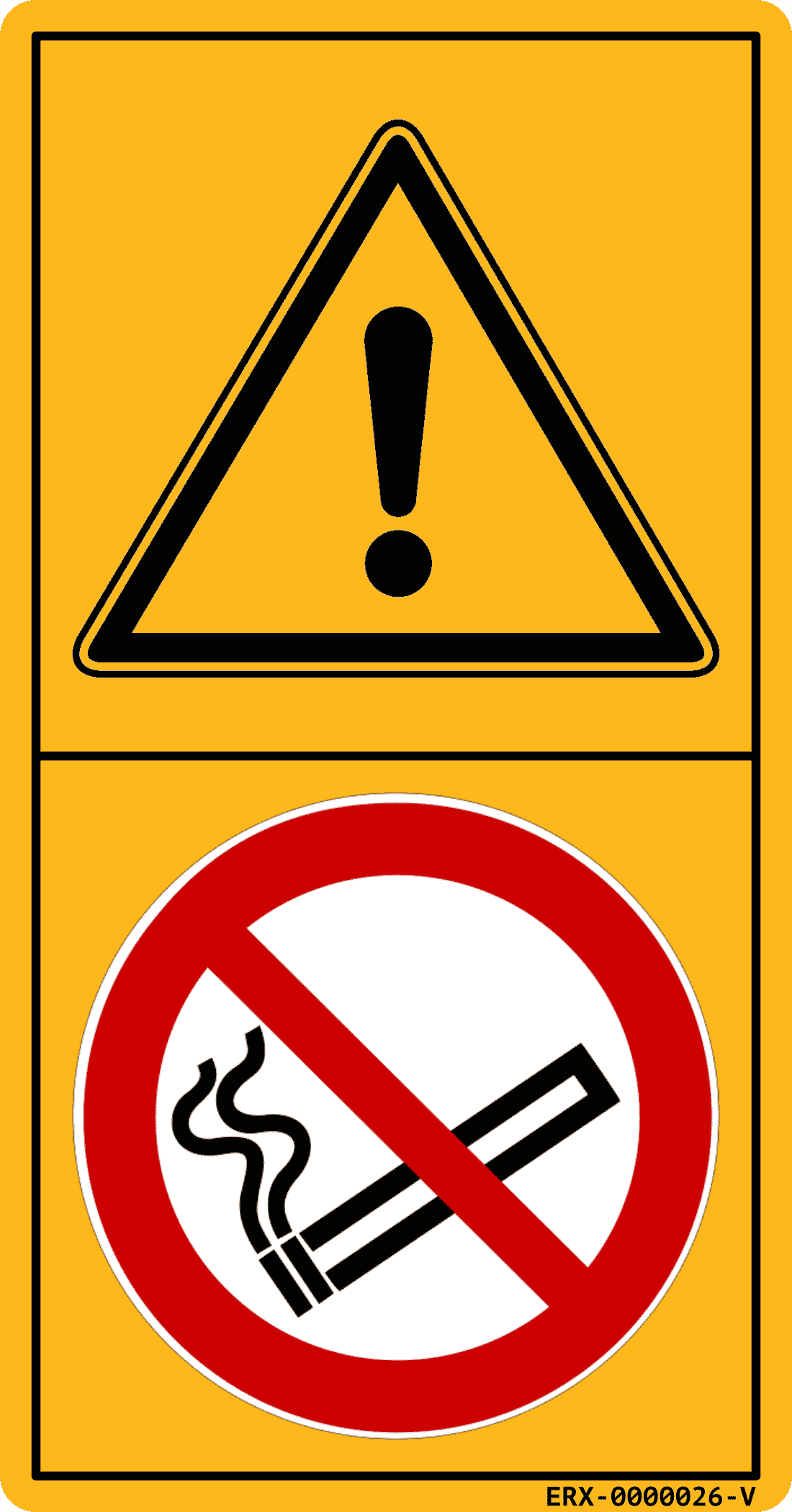

Smoking or vaping

Do not smoke or vape in the proximity of phytosanitary liquids.

Inhalation

Danger of inhalation of harmful or toxic substances. Wear a dust mask before leaving the cabin.

Transport

Never place or carry people, animals, or objects on the machine, whether it is stationary or in motion.

Pollution

Risk of pollution. It is strictly forbidden to dispose of the products in the environment or in the sewers.

Lubrication

Do not lubricate while the machine is in operation.

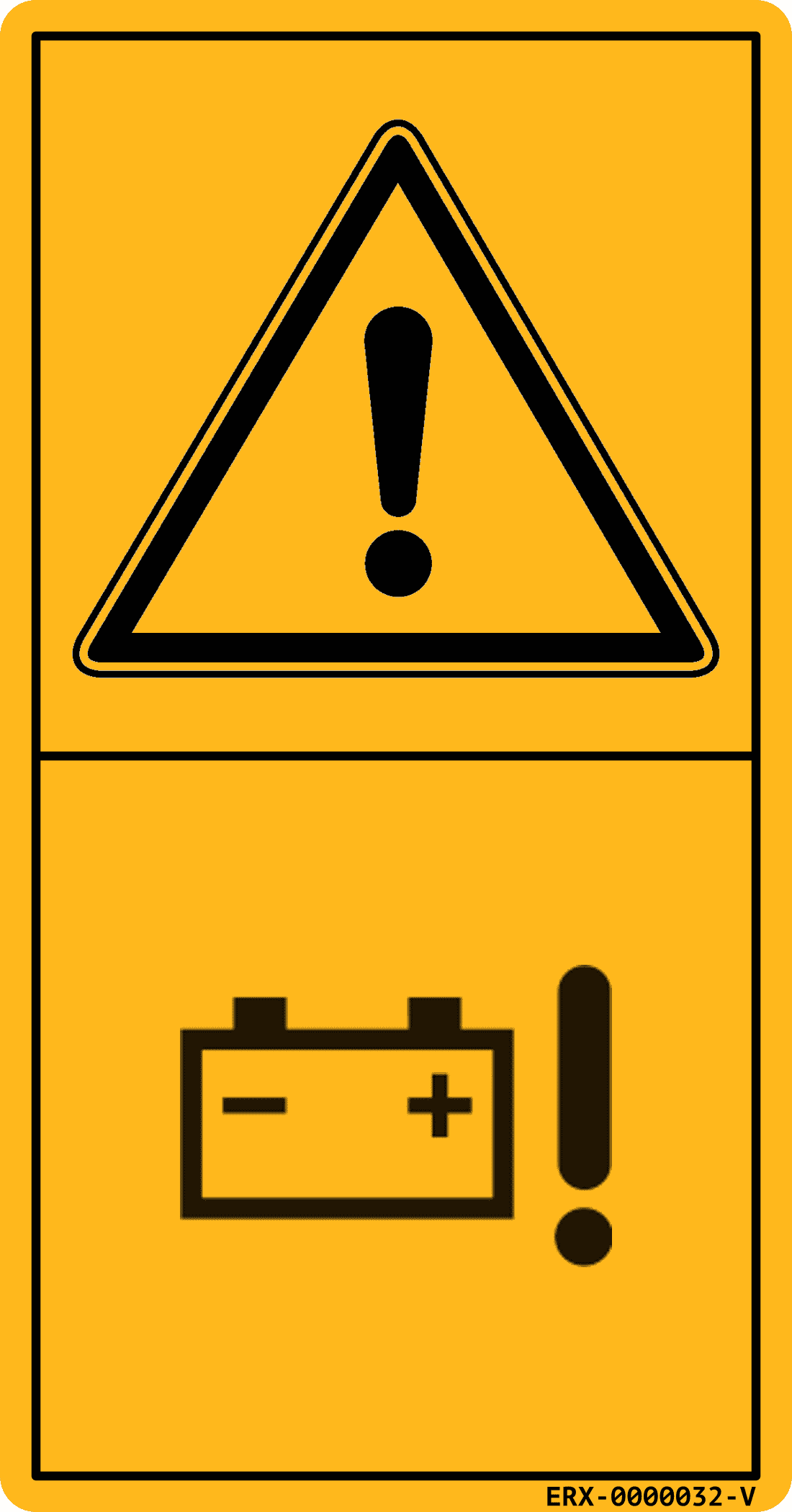

Batteries

The system is powered by batteries. They must be unplugged during interventions that require a complete disconnection of the power supply.

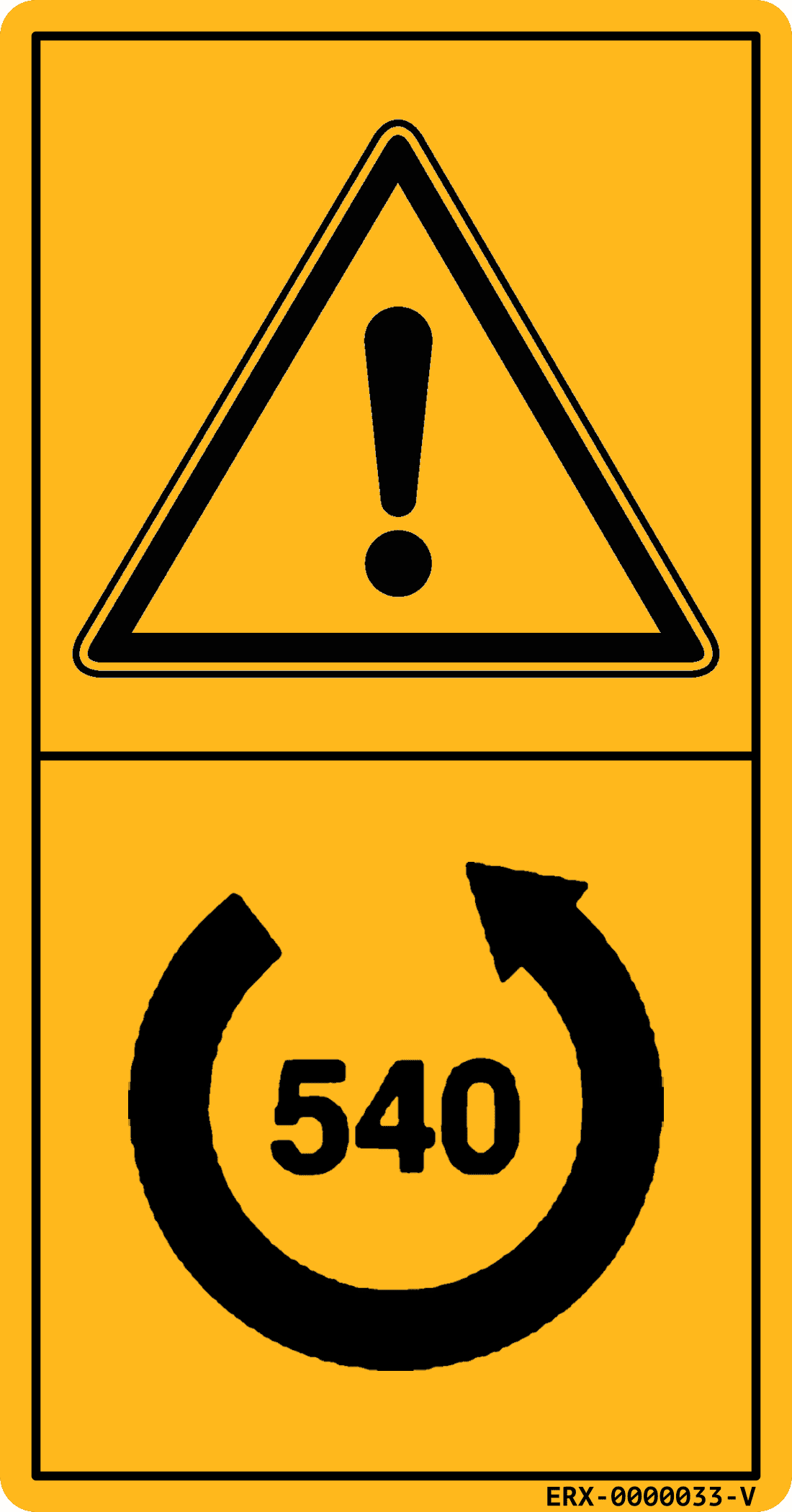

Power take-off (PTO)

Make sure that the direction of rotation and the number of revolutions of the tractor’s PTO are correct.

Distribution system pressures

Observe the distribution system pressures indicated in the manual.

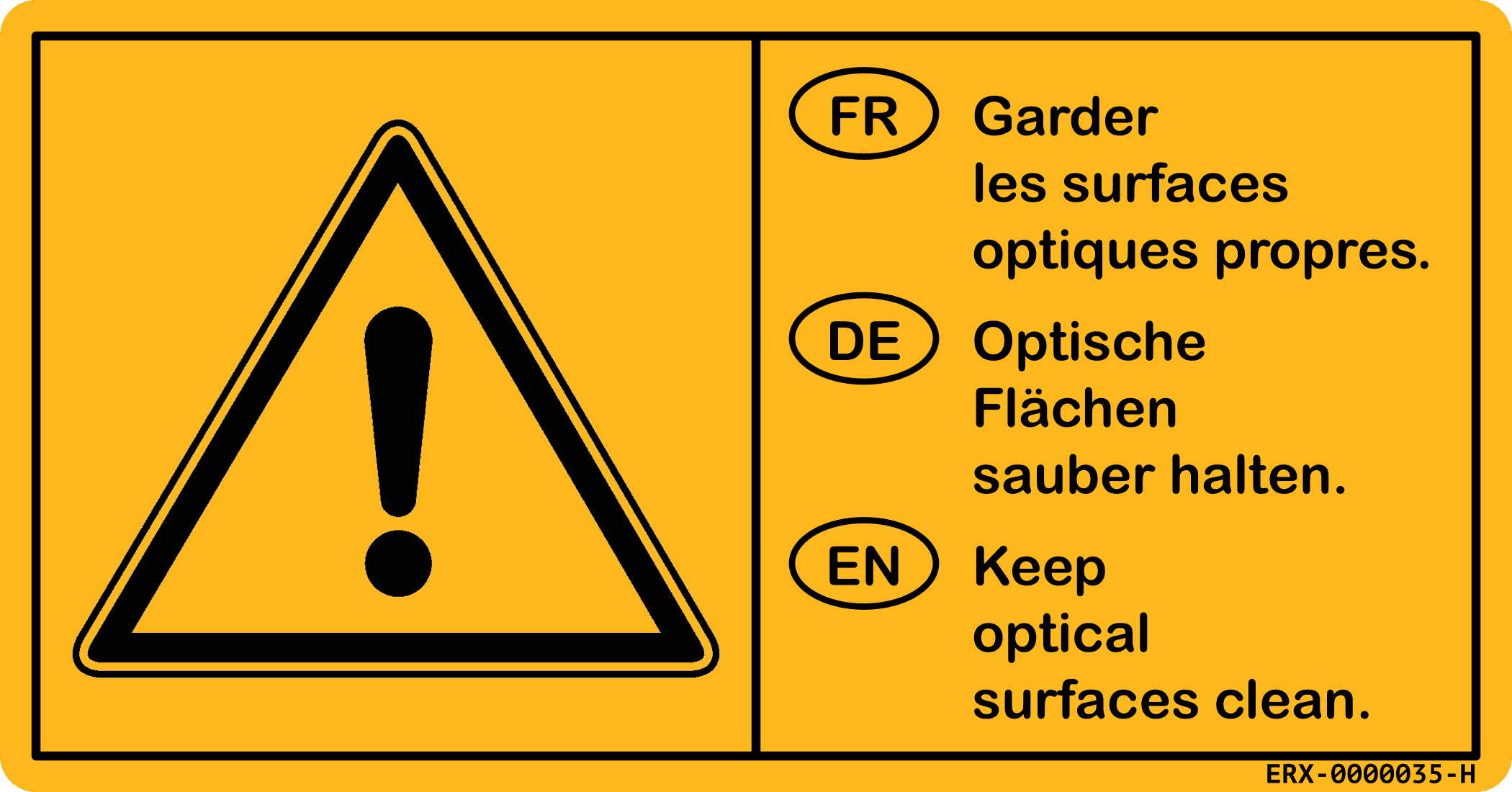

Maintenance of flash boxes

-

The 6 flash units must be maintained with the utmost care.

-

Keep optical surfaces clean.

-

Do not use a pressure washer to clean the flash units.

Travelling on the road

It is the operator’s responsibility to comply with all local, state, and federal requirements applicable to transport of the ARA™ machine on public roadways, including any height limitations and flashing light requirements or prohibitions. It is the sole responsibility of the purchaser to obtain any licensing or signage as may be required to comply for transport on public roads.

The following points should be checked before operating the machine on the road:

-

Respect of the traffic regulations in force.

-

Ensure that the machine is of the correct size.

-

If not, comply with the requirements of the exceptional transport regulations.

-

Check that lighting and signalling devices are correct, clean, and functional. Replace defective equipment.

-

Observe the maximum speed limit. In any case, the speed of travel must not exceed 40 km/h | 25 mph.

-

Before moving the machine onto the road, place the machine in the transport position according to the instructions in this manual.

INFORMATION

Always respect the traffic regulations in force.

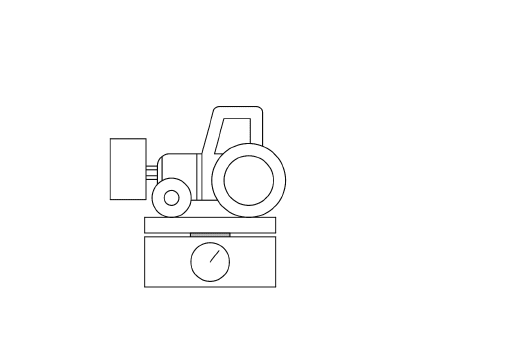

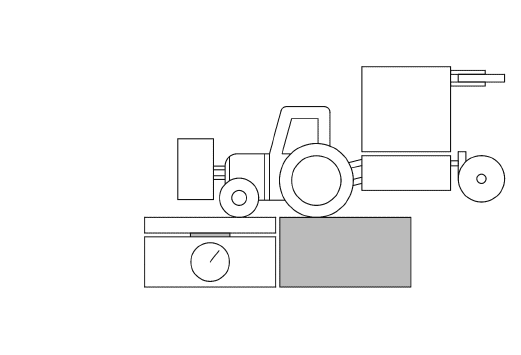

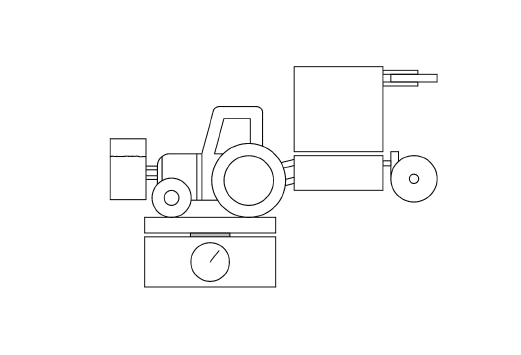

Gross vehicle weight and axle load

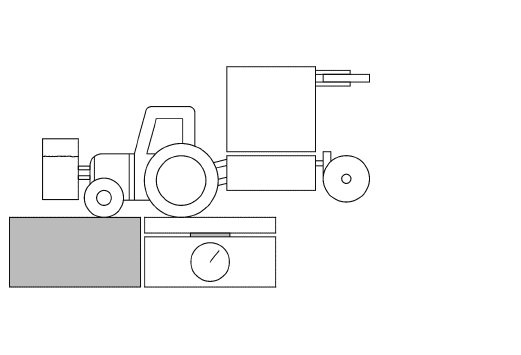

The following illustrations are not contractual, they are only intended to illustrate the method to be followed.

Before using the machine on public roads, check that all these conditions are met to comply with the legislation of the country where the machine is used:

-

The coupling of front and/or rear implements to the three-point linkage must not lead to the total permissible laden weight (GVW) being exceeded.

-

The front and/or rear attachment of implements to the three-point linkage must not lead to the maximum permissible load on the tractor tires being exceeded.

-

The front axle load of the tractor must always be at least 20% of the tractor’s empty weight.

For machines with hoppers or tanks:

-

If the total weight of the combination exceeds the permissible gross vehicle weight of the tractor in accordance with the country’s legislation, empty the hopper for driving on public roads.

-

In any case we recommend driving on public roads with empty hoppers and tanks.

Description of the symbols

|

Symbol |

Unit |

Description |

|---|---|---|

|

T |

kg | lb |

Tractor empty weight (without driver and passengers, with full fuel tank) |

|

GVWR |

kg | lb |

Gross Vehicle Weight Rating |

|

T1 |

kg | lb |

Empty load on the front axle of the tractor |

|

T2 |

kg | lb |

Empty load on the rear axle of the tractor |

|

t |

kg | lb |

Axle loads (tractor + machine) |

|

t1 |

kg | lb |

Front axle load (tractor + machine) |

|

t2 |

kg | lb |

Rear axle load (tractor + machine) |

|

t1 max |

kg | lb |

Maximum permissible load on the front axle of the tractor depending on the tires |

|

t2 max |

kg | lb |

Maximum permissible load on the rear axle of the tractor depending on the tires |

|

M1 |

kg | lb |

Total weight of front equipment |

Procedure to follow

Conditions valid for all the measures below:

-

The tractor must be refueled.

-

No one is in the tractor cab or on the scale.

Measurement of the tractor’s empty weight (T)

-

Machine uncoupled.

-

Empty front tank.

-

Position the tractor so that both axles are on the scale.

-

Read the value indicated by the scale. This value is the empty weight of the tractor (T).

Checking the load on the front axle (t1)

-

Machine hitching up to the tractor.

-

Machine in transport position.

-

Position the tractor so that only the front axle is on the scale.

-

Measure the front axle load (t1).

-

If necessary, add water to the front tank until t1 ≥ (20% × T).

-

The weight of the equipment attached to the front three-point hitch, including the volume of water added, is the ballast weight (M1).

Gross Vehicle Weight Rating (GVWR) verification

-

Position the tractor so that both axles are on the scale.

-

The other measuring conditions are the same as those obtained at the end of the previous step.

-

Read the measured value indicated by the scale. This value is the total weight (t).

-

Check in the technical documentation of the tractor that the measured value (t) is lower than the value of the Gross Vehicle Weight Rating (GVWR).

Checking the load on the rear axle (t2)

-

Position the tractor so that only the rear axle is on the scale.

-

The other measuring conditions are the same as at the end of the previous step.

-

Read the measured value indicated by the scale. This value is the load on the rear axle (t2).

-

Check in the technical documentation that:

-

The value of t2 is lower than the maximum permissible load on the rear axle of the tractor.

-

The characteristics of the tires and rims are in conformity.

-

Precautions to take before using the machine

-

Wear clothing that fits snugly to the body to avoid being caught in moving parts.

-

Ensure that personal protective equipment suitable for the intended work is available (Personal protective equipment (PPE)).

-

Position remote controls (ropes, cables, rods, etc.) so that they cannot accidentally initiate a manoeuvre that could cause an accident or damage.

-

Check that the wheels and their supports are properly secured.

-

Check that the machine and tractor tire pressures are correct.

-

Before each use of the machine, check that all protective devices are in place and in good condition.

-

Replace any worn or damaged guards immediately.

Precautions to take before using the control box

-

Place the control box in such a way that it cannot interfere with other tractor controls and cannot be operated accidentally.

-

Before switching on the control box, make sure that no one is in the area where the machine is being operated: switching on the control box can have consequences for the machine..

Precautions to take when using the control box

-

Do not handle the control box while someone is working on the machine.

-

Before doing any maintenance or repair work on the machine, turn off the power to the control box.

Precautions to take before using the control panel

-

Make sure that the battery level is sufficient for use without connecting the charging cable.

-

Check that the charging cable is working properly.

Precautions to take when using the machine

-

Make sure no persons, animals or objects are near or in the path of the machine.

-

Always work in forward gear.

-

Keep away from moving parts (power take-off, alternator).

-

In case of collision with an obstacle:

-

Disengage the PTO.

-

Turn off the tractor engine.

-

Remove the ignition key.

-

Wait until all components have come to a complete stop.

-

Check that the machine is undamaged and safe to operate.

-

Precautions to be taken during maintenance or repair work

-

Use personal protective equipment suitable for the intended work (Personal protective equipment (PPE)).

-

Maintenance or repair work may only be carried out by qualified personnel, especially work on safety-relevant components such as pressure vessels.

-

Always use tools that comply with regulatory requirements.

-

Place the machine on the ground.

-

Place the modules in the desired position for the intervention.

-

If work is to be carried out with the modules raised, make sure that the safety hooks are properly locked.

-

Disengage the PTO.

-

Stop the tractor engine.

-

Remove the ignition key.

-

Wait for all components to come to a complete stop.

-

Depressurize the hydraulic system.

-

Allow hot parts of the machine to cool down.

-

Before working on the electrical system, or before welding operations on the hitch up machine:

-

Disconnect the electrical connections between the machine and the tractor.

-

Disconnect the batteries.

-

Disconnect the alternator.

-

-

Do not weld, braze, or use a flashlight:

-

Near pressurized fluids or flammable products.

-

Near electronic boxes.

-

-

Always use original spare parts.

-

Follow all recommendations regarding maintenance intervals, tightening torques and lubricants, etc., contained in this manual.

Waste disposal

-

Observe the applicable waste disposal regulations.

-

Technical fluids such as oil, grease, and fuels as well as plant protection products must never be discharged into the environment or into the sewer system.

-

If necessary, call in a specialist company.

General recommendations

-

The machine is designed for spraying crop protection agents in the agricultural field and must not be used for any other purpose.

-

The slope of the ground must not exceed the limits indicated by the tractor manufacturer.

-

Weather conditions as well as the nature of the terrain can influence the limit parameters.

-

Make sure a first aid kit is always available.

-

Keep untrained people away, especially children.

Precautions to take before starting the machine

-

Before starting the machine, especially after a long period of storage, make sure that no loose objects have been deposited inside the tanks or in other parts of the machine.

-

Sit on the seat in the cab to start or manoeuvre the machine.

-

Before starting the engine, make sure the parking brake is on and the multi-function lever is in neutral.

-

If the tractor is operated in a room, make sure the exhaust is properly vented.

-

Keep untrained persons, especially children, away.

-

Warn of starting by sounding the horn several times.

Precautions to take when stopping the machine

-

Preferably choose a flat, level parking space.

-

If the parking space is on a slope:

-

Make sure the tractor is facing up the slope.

-

-

Lower the machine’s three-point hitch so that the wheels touch the ground.

-

Before leaving the tractor cab:

-

Apply the parking brake.

-

Put the multi-function lever in neutral.

-

Turn off the engine.

-

-

If the machine is to be left unattended:

-

Remove the ignition key.

-

Turn the battery switch to the off position.

-

Pump

-

If in doubt about the use of a plant protection product, consult your Ecorobotix dealer.

-

Do not connect the external suction to a pressurized line (water supply).

-

The maximum acceptable suction pressure is 0.1 bar | 1.5 psi.

-

Do not suck at a depth greater than 3 m | 9′10″ from the pump position.

-

Do not pump seawater or water with high salt concentration.

-

Do not pump flammable liquids.

-

Do not pump any solution with temperature above 40°C | 104°F or below 5°C | 41°F.

-

The working pressure must not exceed the maximum working pressure.

Risk of burns

The outer surface of some parts can reach high temperatures and cause burns if touched.

-

Be especially careful when working near hot surfaces.

-

Wear protective gloves.

-

If possible, let the machine cool down before working on it.

Precautions and prevention against fire risks

The machine works with highly flammable products.

Therefore, there is a real risk of fire that may result from:

-

Overheating of the friction clutch of the PTO. Take care not to let the friction clutch slip excessively. As soon as smoke appears in the transmission, stop the machine immediately and let the clutch cool down outside the building.

-

Twine or other material being wrapped around the power take-off shaft. Before each use of the machine, check the power take-off and its extremities, and remove any wound or accumulated product.

-

Deteriorated bearings. Grease the bearings regularly and check their condition.

-

Sparks caused by the presence of stones or metallic bodies in the straw.

It is strongly recommended to have a tested and maintained fire extinguisher on board the tractor. Recommended types: water spray + additive, ABC powder.

-

It is strictly forbidden to use the machine in a stationary position inside a building.