Bleeding air from the circuit

When air is present in the system, the pump must be primed. The main causes of air in the system are as follows:

-

The pump has been switched off for a long time.

-

The suction filter has been opened.

-

The selected tank is empty and the pump is switched on.

-

The symptom of air in the circuit is as follows:

-

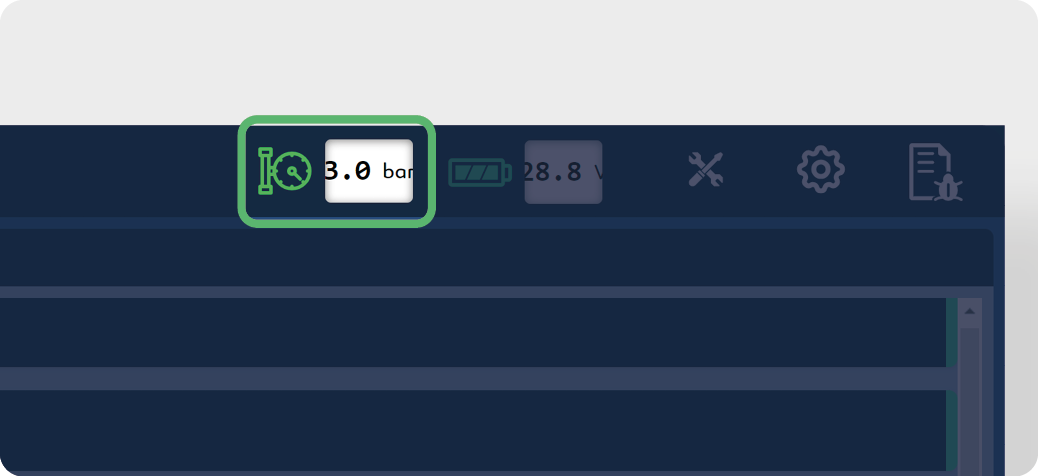

The pressure varies rapidly and with amplitudes greater than ± 0.5 bar | 7.25 psi.

To prime the pump:

-

Make sure the pump is switched off.

-

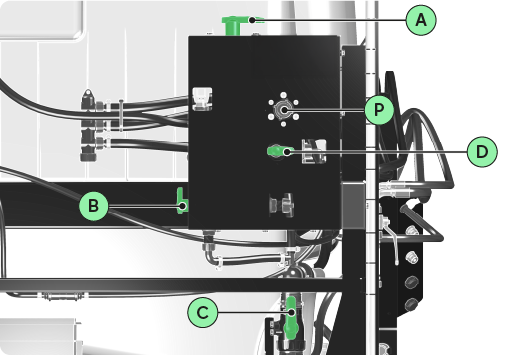

Position the valves:

-

Valve A : position 2

-

Valve B : position 4

-

Valve C : position 5

-

Valve D : position 100%

-

-

Engage the pump.

-

Wait for the pressure to stabilize.

-

If the pressure does not stabilise, check that there are no leaks and ensure that the liquid level in the selected tank is sufficient (position 5 or 6 of valve C).

-

To adjust the working pressure, refer to the Adjust the working pressure chapter (Adjusting the working pressure).

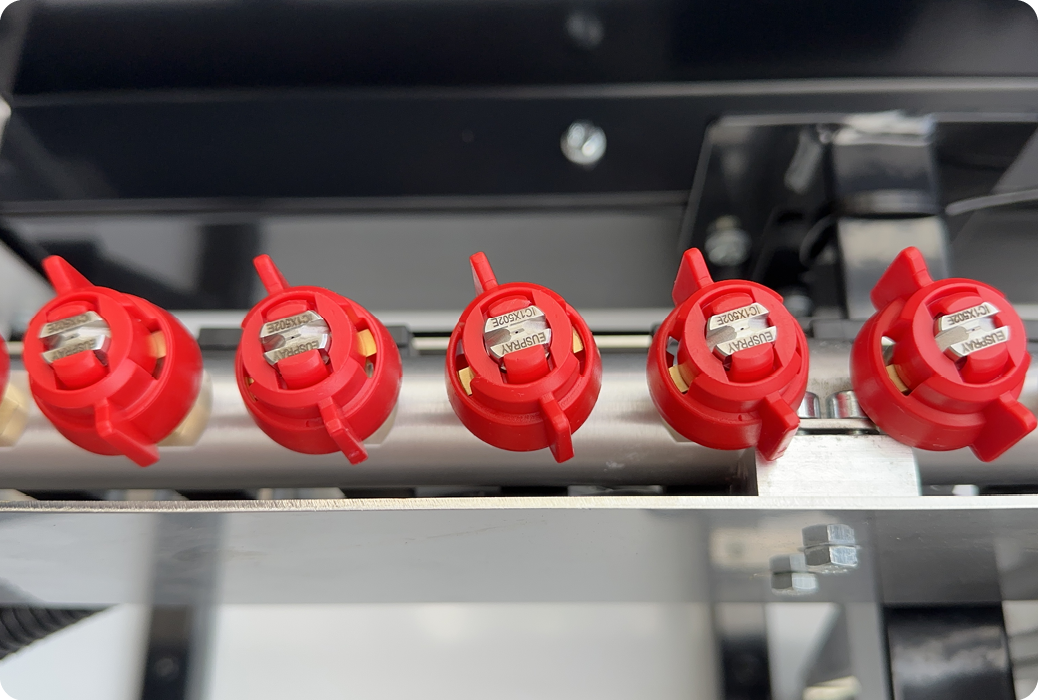

Checking nozzle orientation

The nozzle angle should be 15°.

The angle can be measured easily using a number 8 open-end spanner. When the spanner grips the nozzle, it should be aligned parallel to the boom.

If a nozzle needs adjusting, do not do it yourself as this could upset the solenoid valve. Contact your dealer.